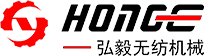

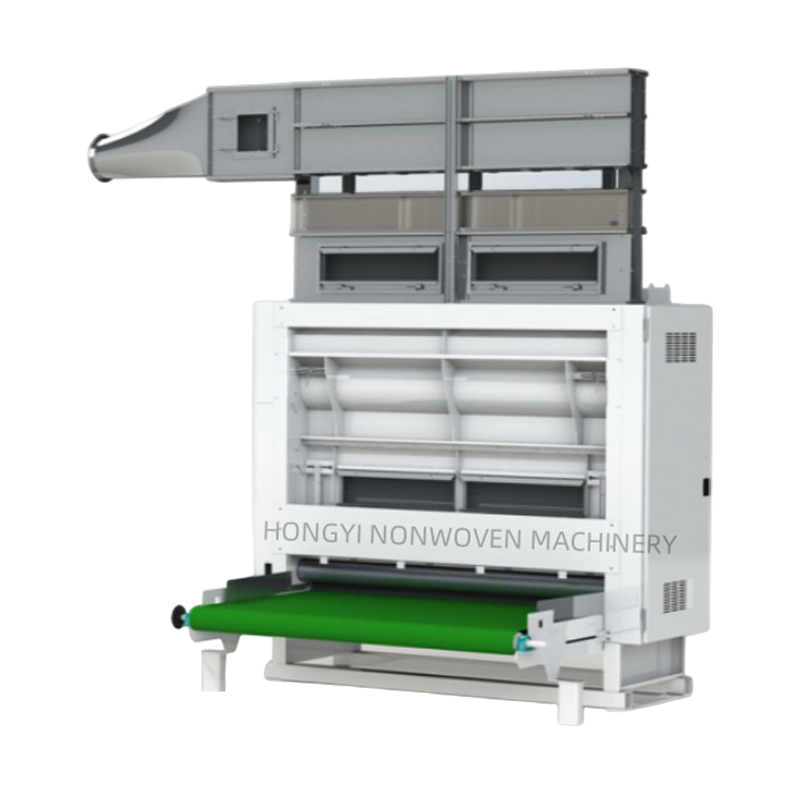

It is usually the last process of the production line. After the product is delivered to the platform, it can be cut horizontally or vertically into the required size according to the set parameter information.

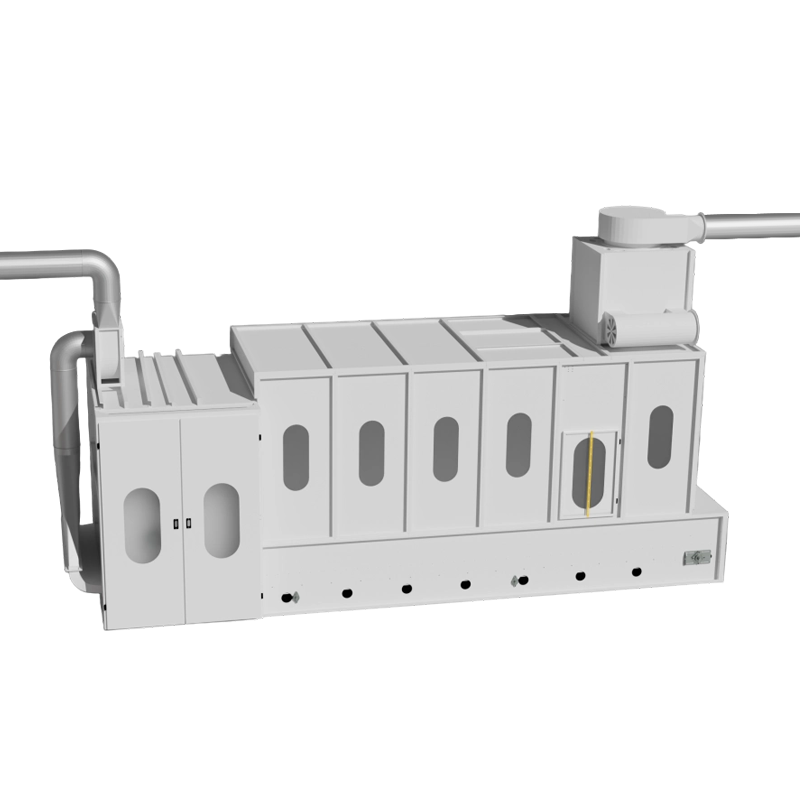

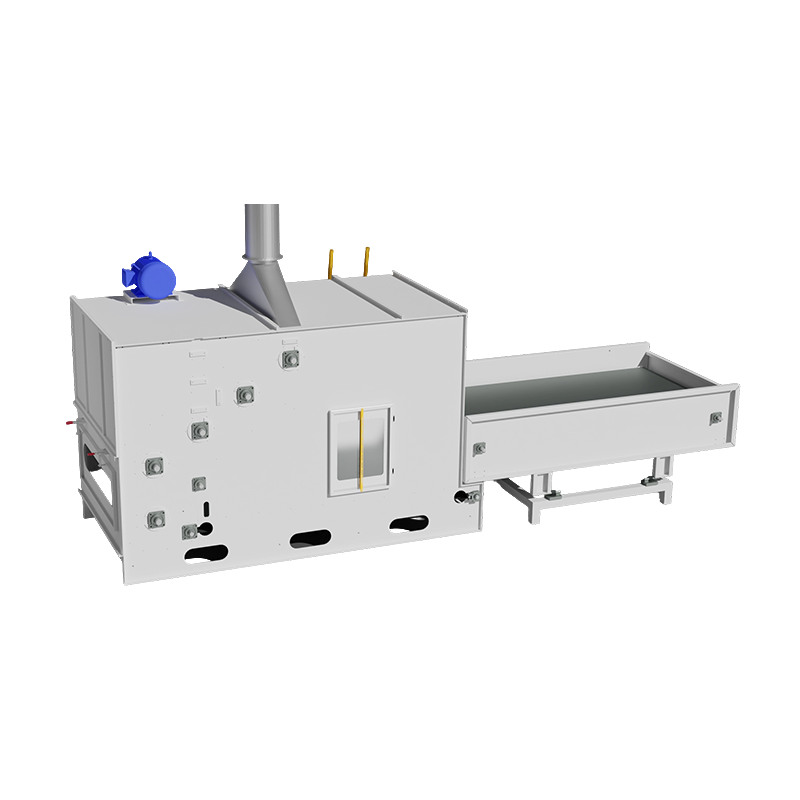

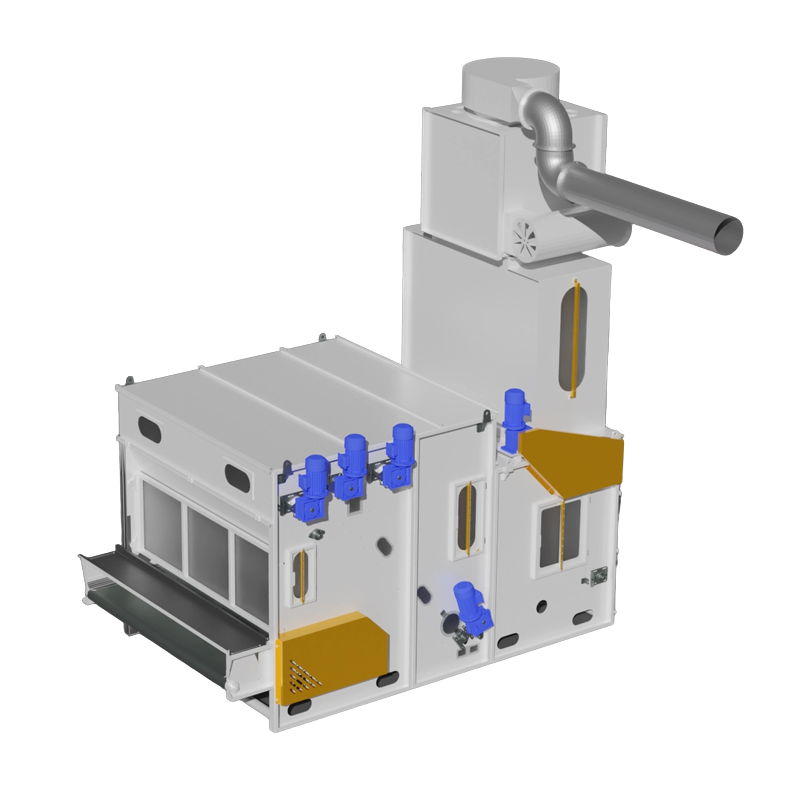

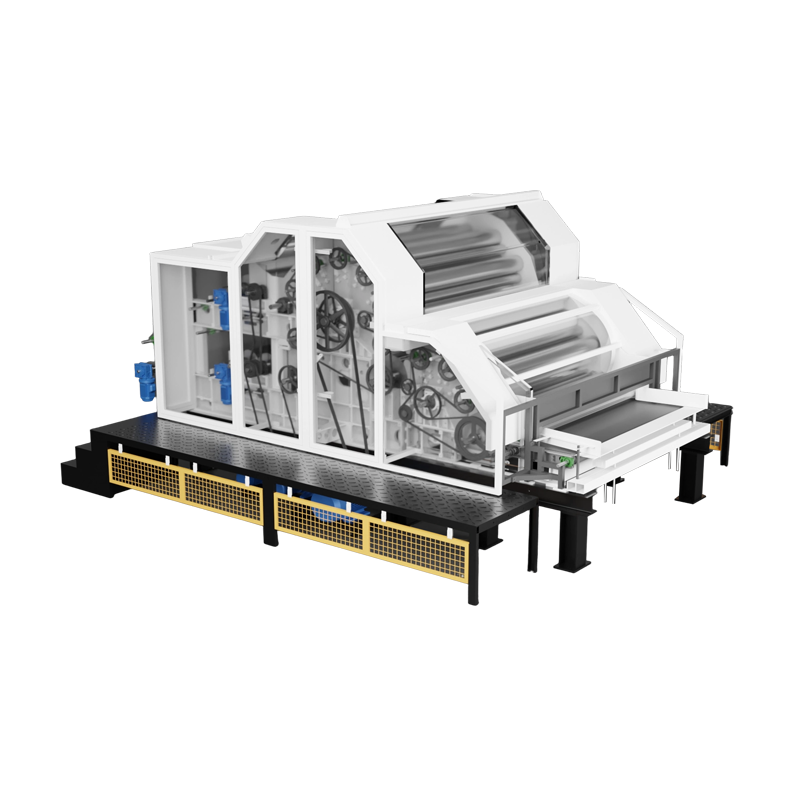

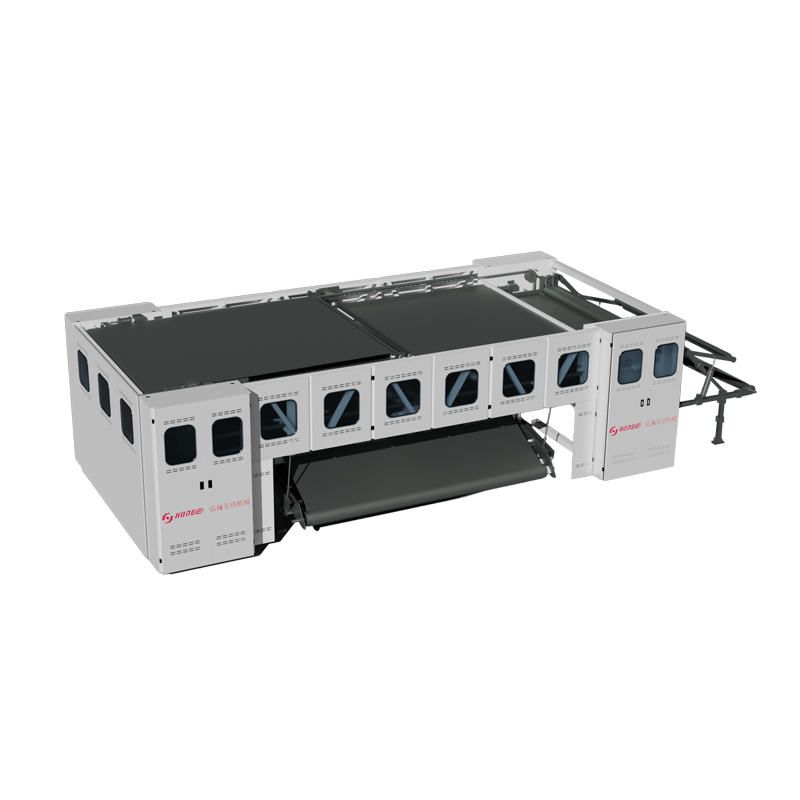

The HYFQ Slitting machine is a cutting machine equipped with an integrated work platform, designed specifically for cutting nonwoven fabrics or scenarios requiring frequent operation. A significant feature distinguishing this machine from similar cutting machines is its robust work platform structure, providing operators with a safe and convenient working area for easy material positioning, measurement, and cutting. By integrating the cutting system with the platform, the HYFQ Cutter Machine With Platform optimizes the human-machine collaboration process, effectively improving operational efficiency and safety when cutting different kinds of nonwoven fabrics. This design reduces the number of material handling operations, helps maintain consistent cutting accuracy, and can adapt to various complex cutting tasks requiring auxiliary operations during processing.

Product Features and Advantages:

Integrated Working Platform: The equipment is equipped with a stable working platform, providing a safe and convenient area for material placement, positioning, and auxiliary operations.

Precision Cutting System: Employs a high-precision cutting mechanism and control unit to ensure accurate cutting dimensions and clean cuts.

Efficient Human-Machine Collaboration: The collaborative design of the platform and cutting system optimizes the operation process and improves the overall efficiency of handling large-sized materials.

Enhanced Safety: The working platform structure helps standardize the operating area and can integrate safety protection devices to reduce operational risks.

Wide Applicability: Can handle various sizes and materials of nonwoven fabric products, and other cutting tasks requiring platform-assisted operation.

Stable and Durable Structure: Both the main body of the equipment and the platform are constructed of robust materials, ensuring long-term stable operation under load.

Convenient Maintenance Design: The rational layout of key components facilitates daily inspection, cleaning, and maintenance.

| Working width | ≤10m |

| Working speed | 0-15m/min |

| Driving motor | 3.75-6.75 kw |

| Winding diameter | ≤1200mm |