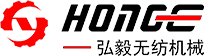

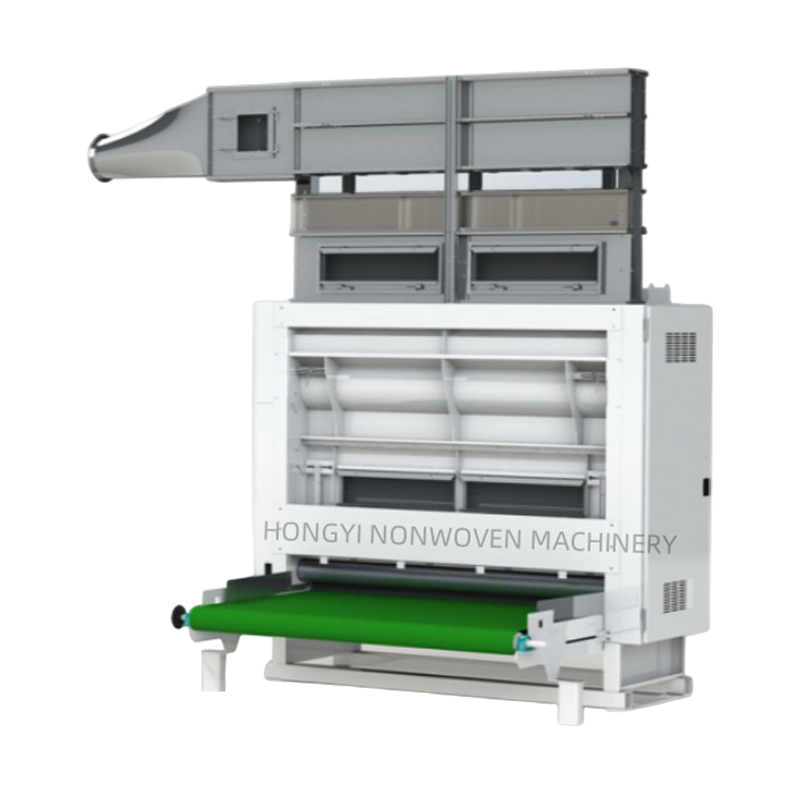

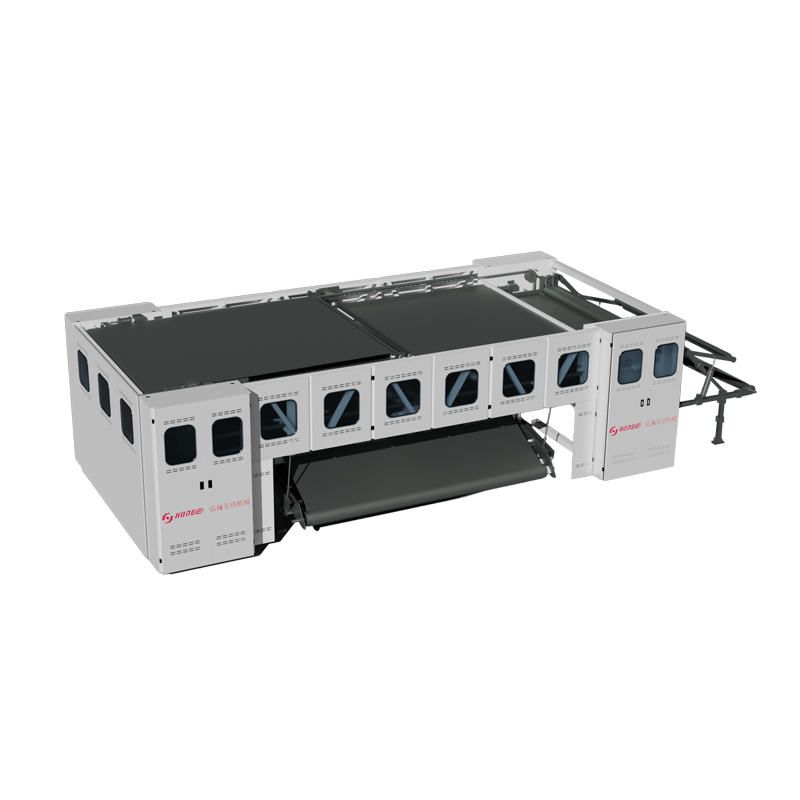

To vertical, it can cross cut the final product

and then neatly roll them to specified roll length.

For soft nonwovens, automatic winding, doffing, roll changing is available as an option if customer choose this nonwoven machine.

Product Features and Advantages

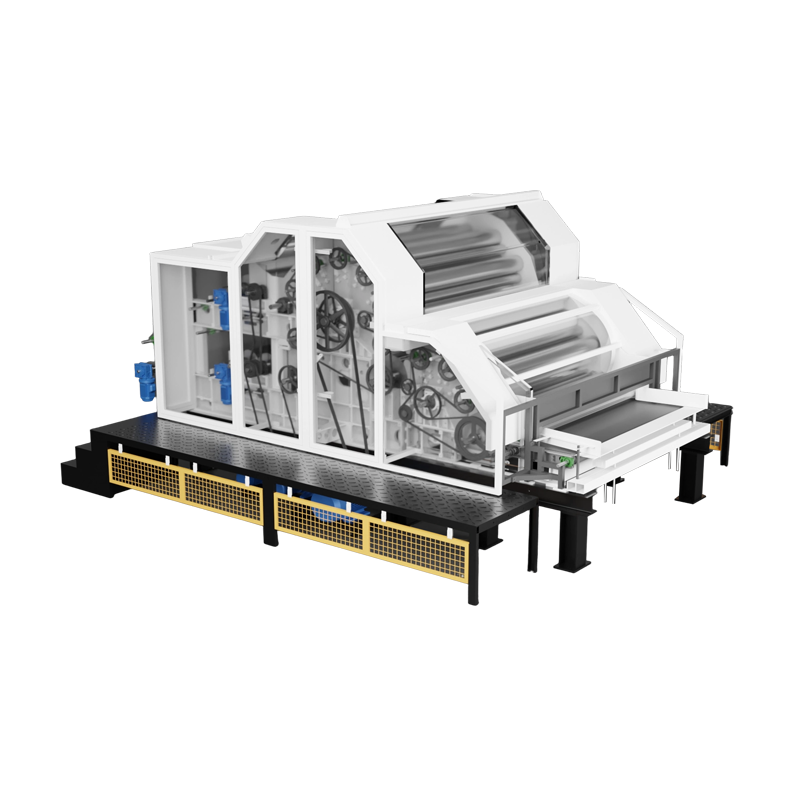

Integrated Design: Winding and cutting functions are integrated into a single platform, simplifying the process and increasing production efficiency.

Precise Length Cutting: A precision control system ensures accurate cutting dimensions and stable product quality.

Automated Continuous Operation: Fully automated operation from material loading to finished product, minimizing manual labor requirements.

Stable Winding Control: Equipped with a tension adjustment system for smooth and uniform winding.

Convenient Operation and Maintenance: User-friendly interface design; key components are easy to maintain.

Material Applicability: Meets the processing needs of various strip and linear flexible materials.

Main Application Areas:Primarily used for cutting and winding textiles, suitable for industrial scenarios where non-woven fabrics need to be cut to the required length and neatly wound, facilitating subsequent processing, storage, or transportation.

| Working width | ≤10m |

| Working speed | 0-15m/min |

| Driving motor | 3.75-6.75 kw |

| Winding diameter | ≤1200mm |