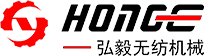

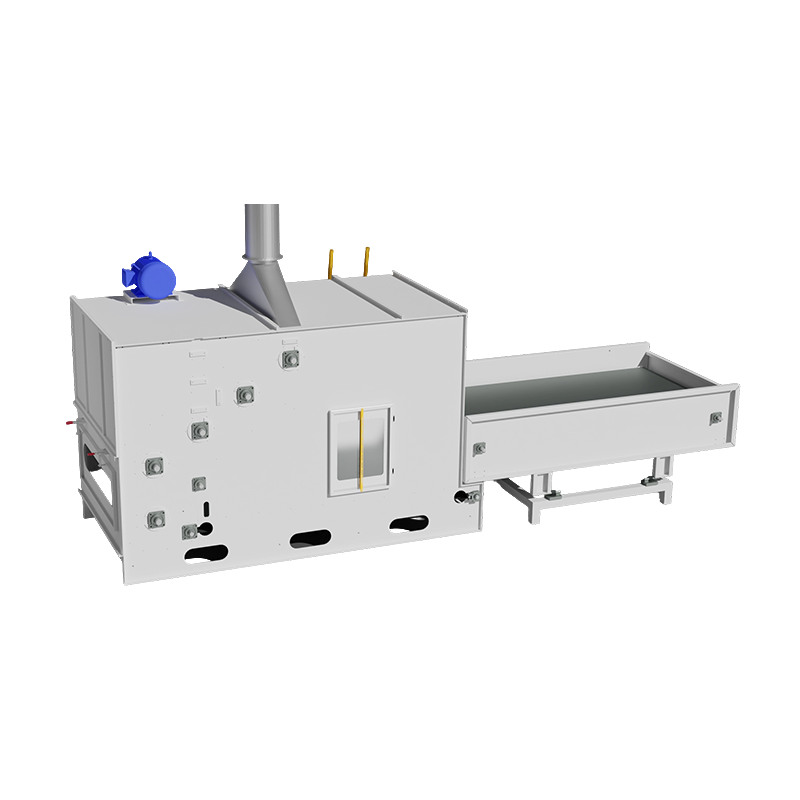

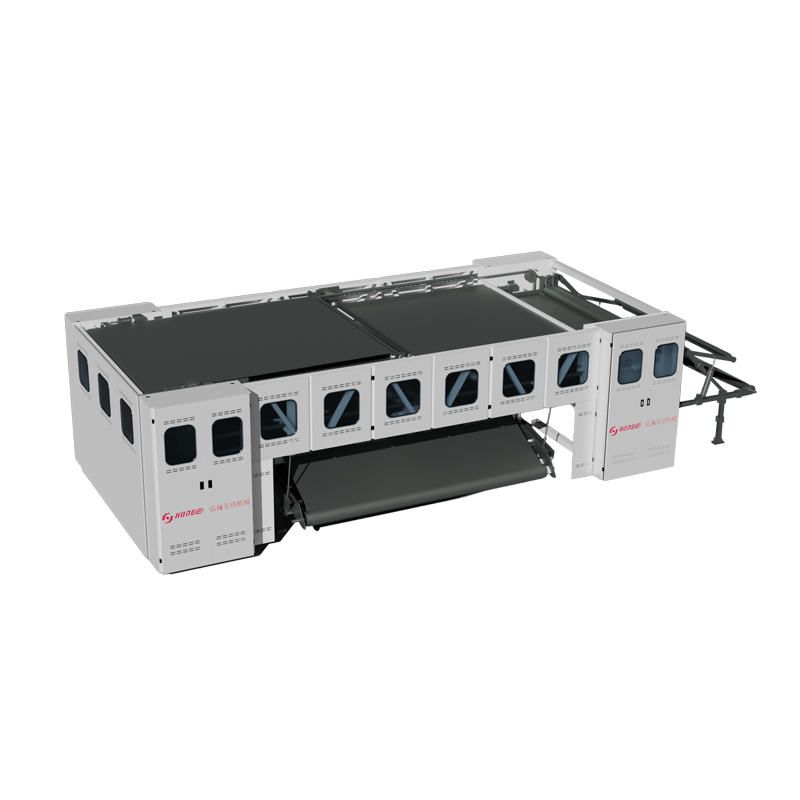

The HYKS Pre&Fine Opener is a fiber raw material opening machine specifically designed for fiber pretreatment processes. Generally placed after the opening machine, the pre-opening machine effectively loosens the fiber raw material after the opening machine and can easily filter out impurities such as metal shavings. The fiber raw material is then further processed by the fine opening machine, resulting in a more uniform fiber structure, thus preparing the raw material for subsequent processes.

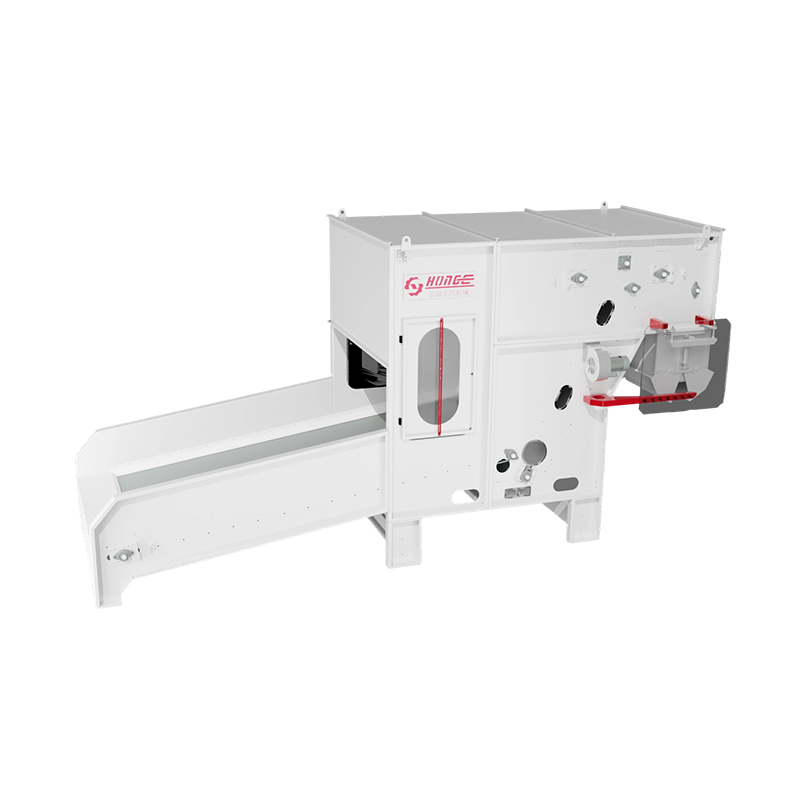

Different production lines have different requirements for the configuration of Pre&Fine Opener. We also have models that integrate the functions of pre-opening and fine opening.

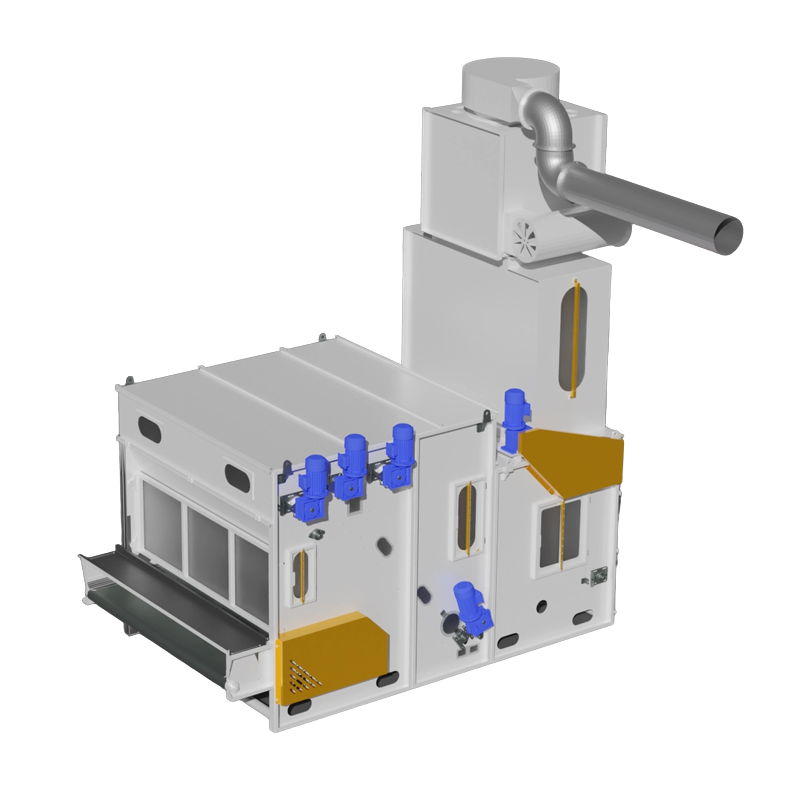

The HYKS Pre&Fine Opener is a fiber opening machine specifically designed for fiber pretreatment processes, integrating pre-opening and fine processing functions. This machine features a unique combined design among similar cotton opening machines, effectively improving fiber processing efficiency and quality by combining a pre-opening stage with a subsequent fine opening stage. The HYKS Pre&Fine Opener not only processing large fiber bundles but also further loosening them into more uniform smaller fiber bundles, providing an ideal fiber state for subsequent processes. This segmented processing method reduces the risk of fiber damage while maintaining high impurity removal efficiency, making it particularly suitable for production scenarios with high requirements for fiber length protection.

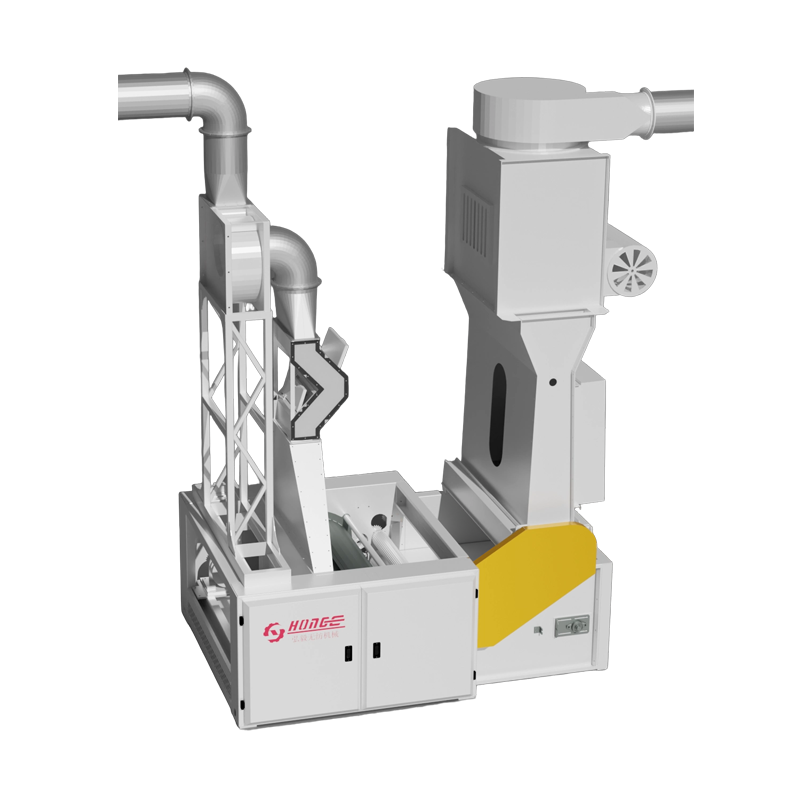

Function and characteristics:

Open and blend the fibers prior to the next processes.

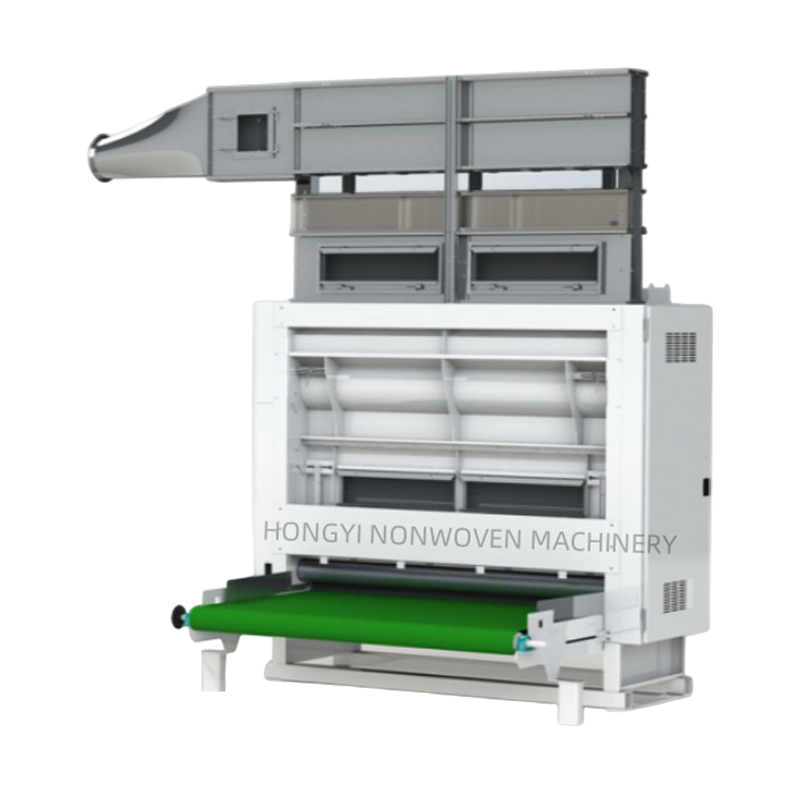

There are several options for the opener depended on the fibers to be used.

These options are as follow:

1.toothed

2.pin plate opener

3. wired opener

A plate magnet is included for metal extraction,alarm and reverse running when jammed.

Structure :

Intergrated numerical control machining of bending frame work for stability.

Even feeding by holding method.

Strong magnet for sucking metal dusts.

Structure of opening roller:rigid aluminium alloy carding plate or carding wire.

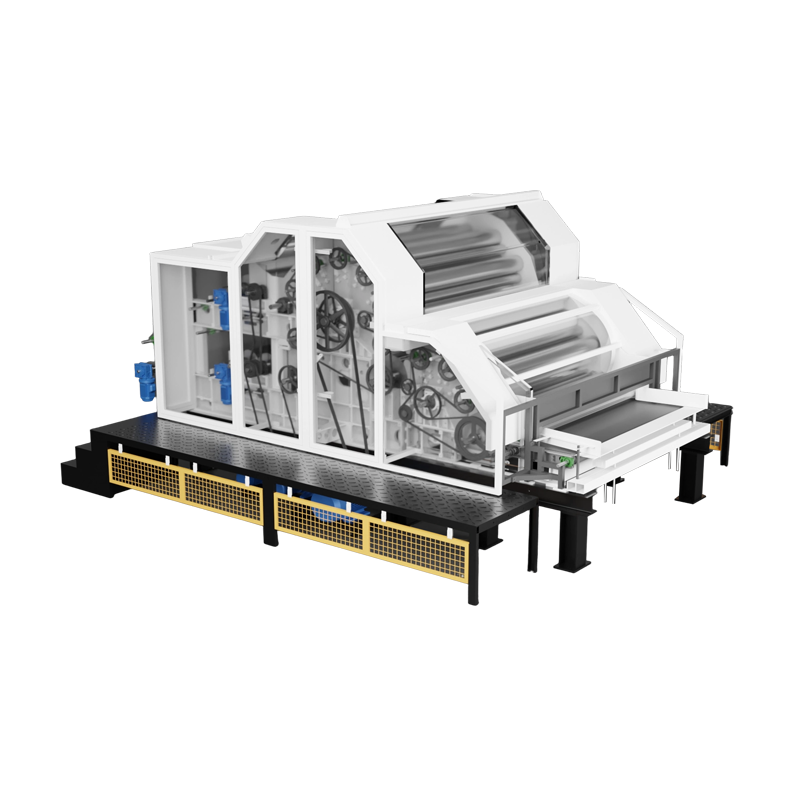

Product Description

|

Working width(mm) |

1000-2000(customized) |

||

|

capacity (kg/h) |

≤1000kg/H/Set |

||

|

feed roller |

Dia.(mm) |

75 |

|

|

|

Rotation speed(r/min) |

16 |

|

|

beater |

Dia.(mm) |

420 |

|

|

|

Rotation speed(r/min) |

900 |

|

|

installed power |

6.95KW |

||

|

dimensions |

4500x1800x1000 |

||

|

net weight |

0.8T |

||