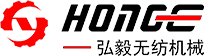

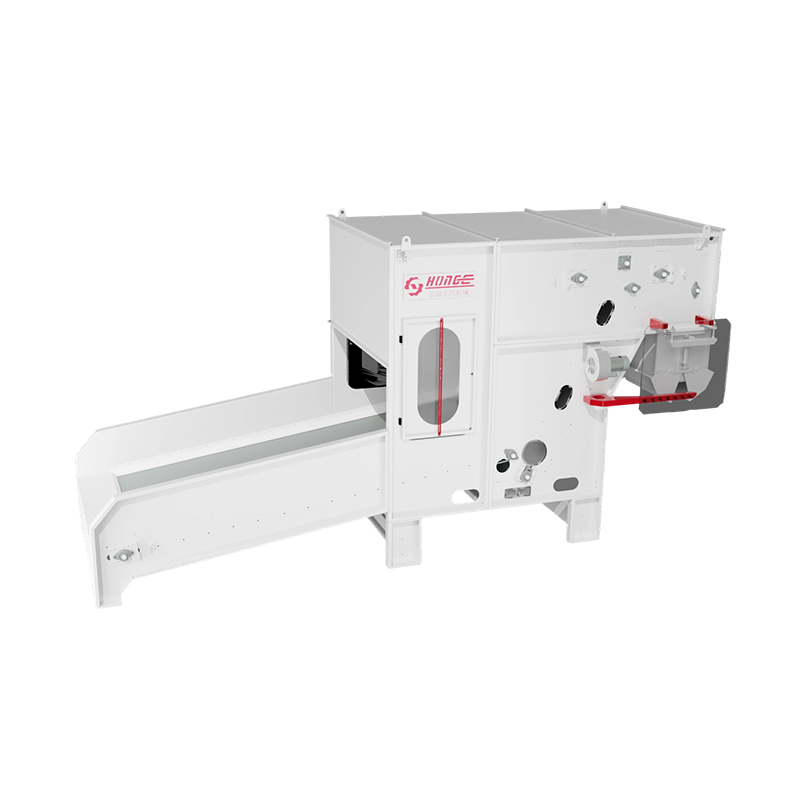

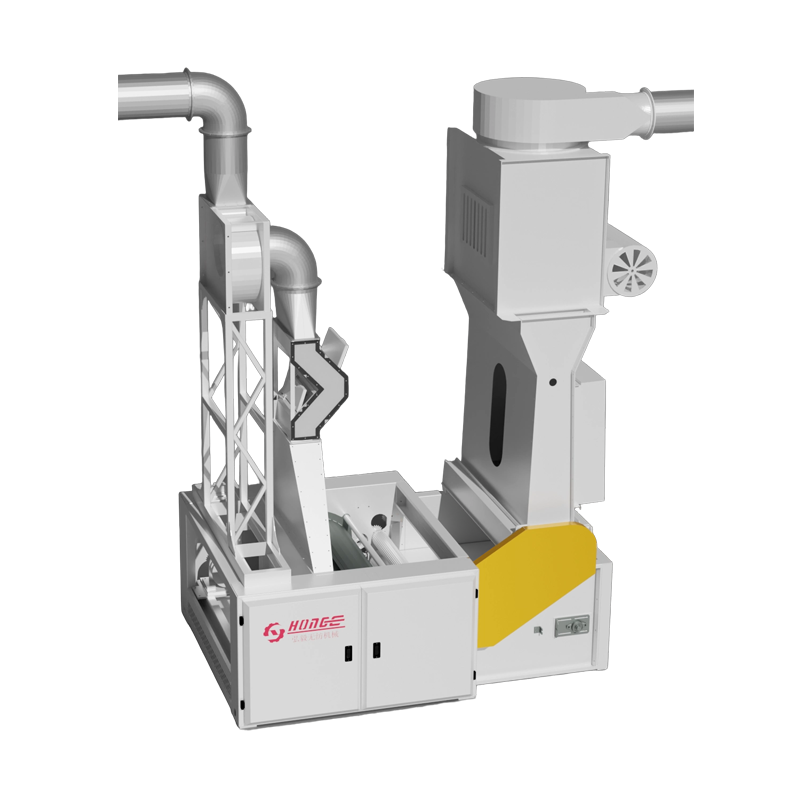

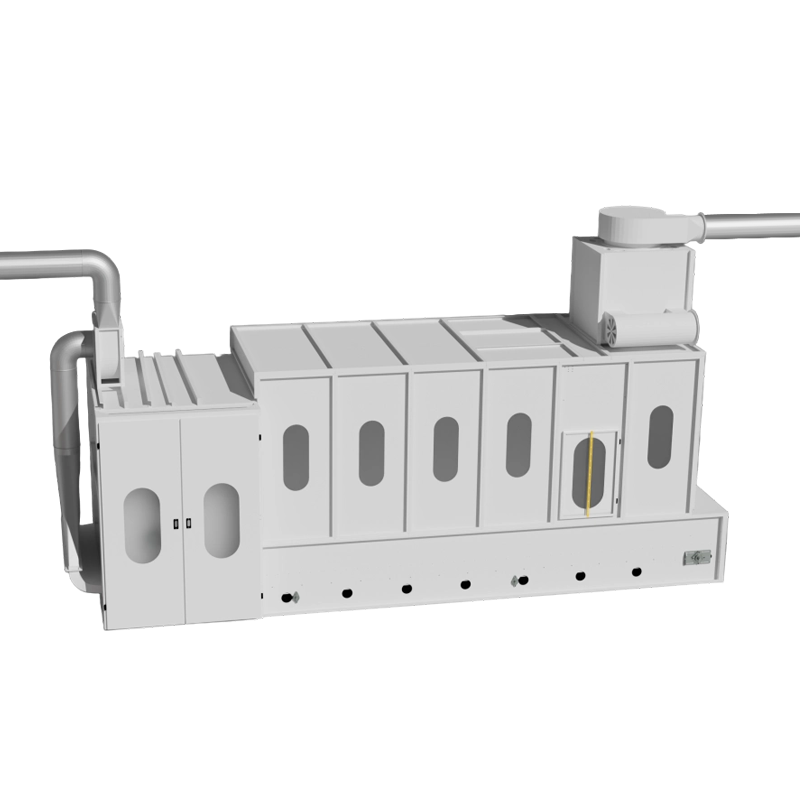

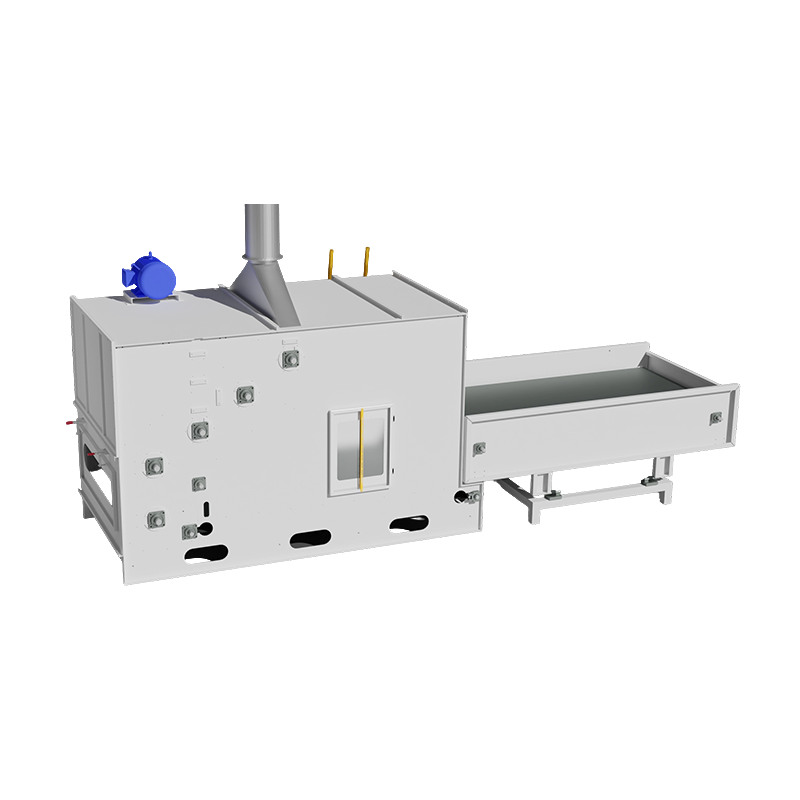

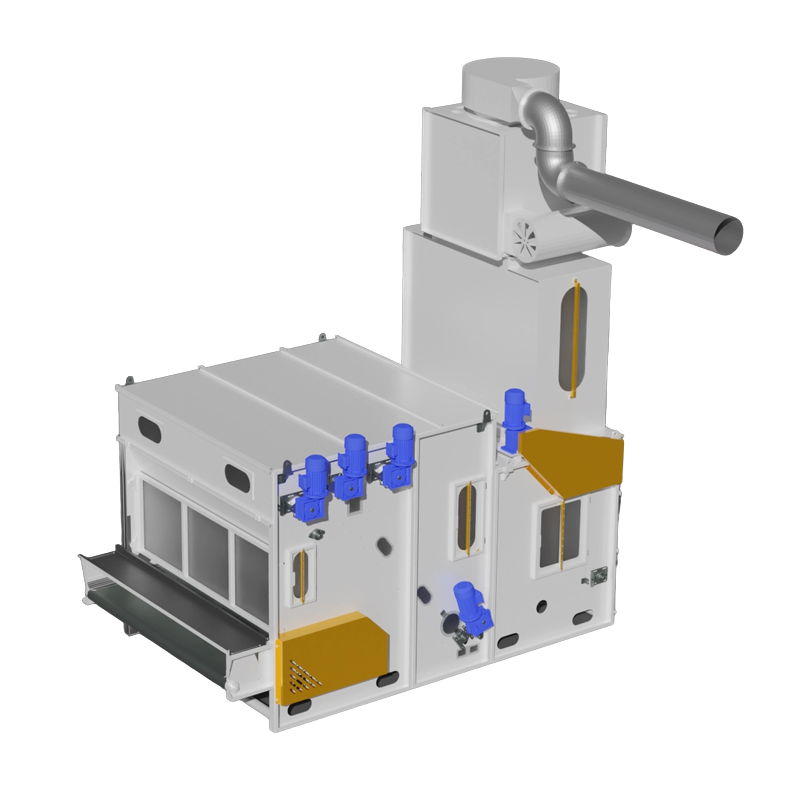

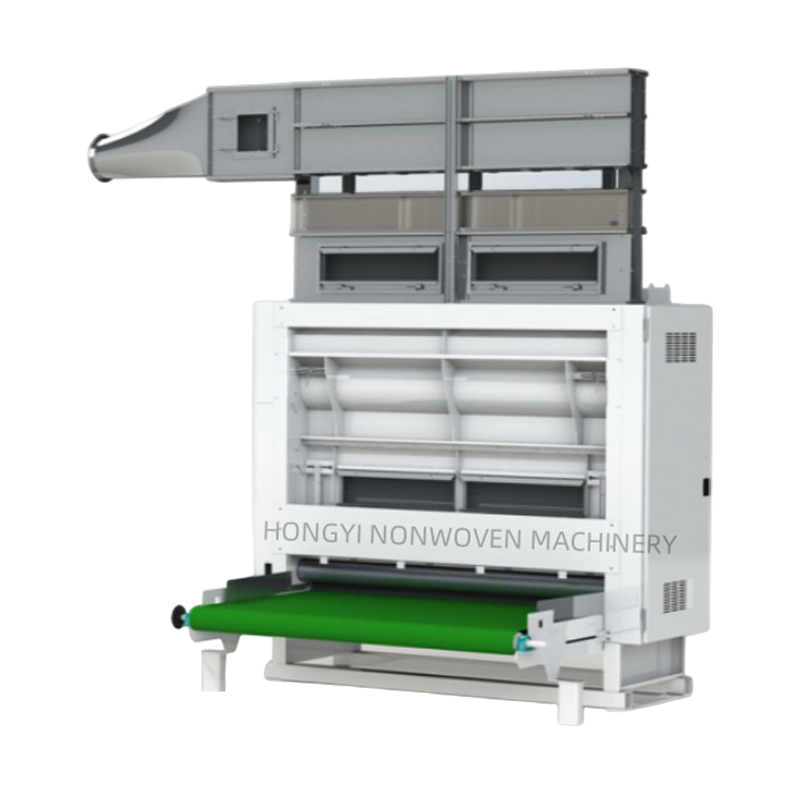

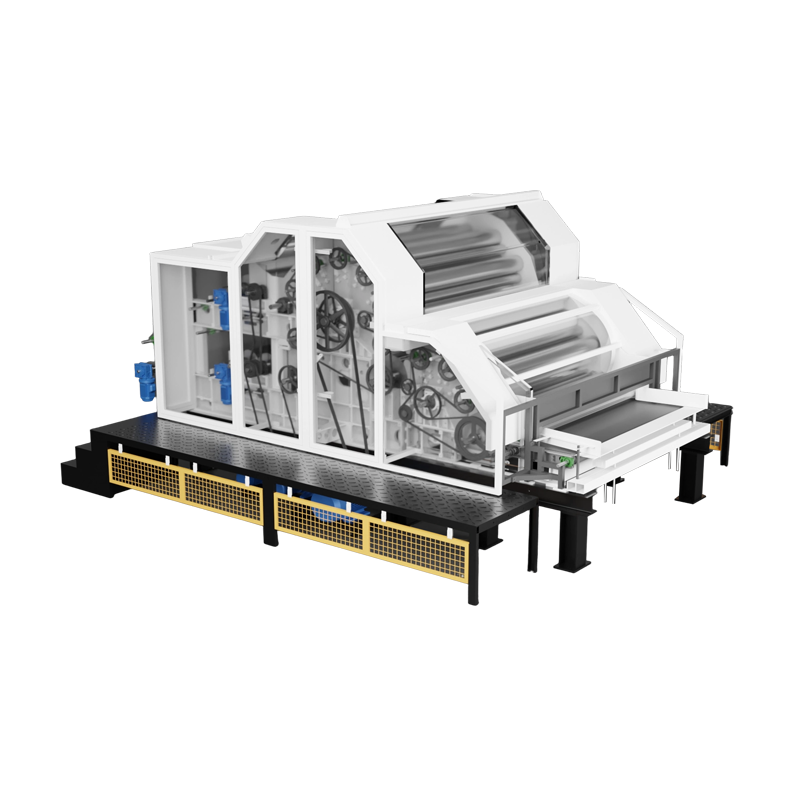

This nonwoven machine is a higher speed unit,aims to to fold and plate the fiber webs from carding machine evenly into the required weight and thickness and then to feed the fiber batt to the next procedure,such as needle punching procedure or thermal bonding procedure,etc.

Structural Features:

The frame is reinforced with 8mm thick steel plates.

Anti-static PVC curtains are used for conveying, folding, and compensation; the bottom belt is made of aluminum alloy.

Each curtain drive roller uses seamless steel pipes, with special reinforcement at the bearing ends.

Web laying and reciprocating motion are precisely controlled in segments.

Reciprocating transmission uses synchronous belt drive.

Functional Characteristics:

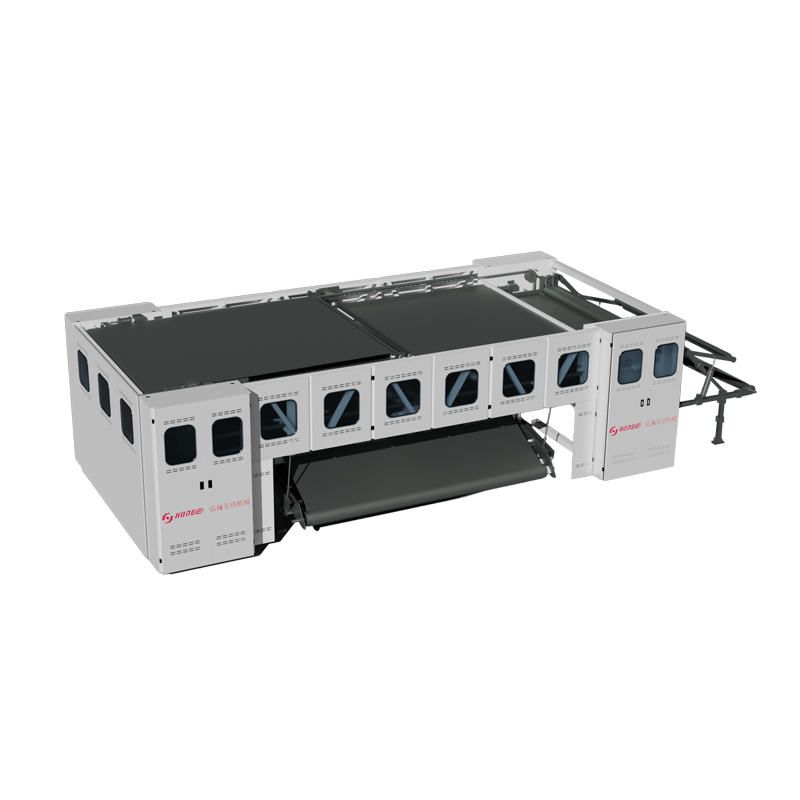

1. To fold and pave the mesh after carding evenly into certain width and thickness, then transfer it to next procedure after pressurization.

2. The output layer has high uniformity, smooth surface, and the product has two edges neatly and trimmingly, and the product quality is stable.

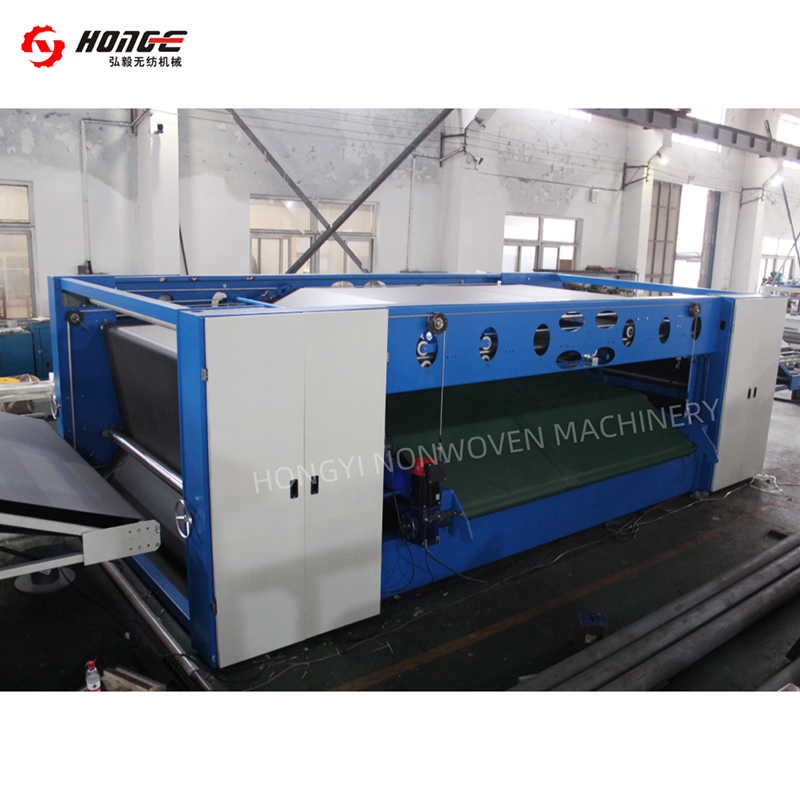

3. The use of high-performance frequency conversion or servo drive, stable operation, fast response.

4. The use of anti-static high-strength carbon curtain, to avoid stress deformation of the cotton layer operation.

5. Adopt unique corrective control principle.

6. Using a data control system, the output uniformity can be fully compensated with actual process requirements.

7. Input and output is controlled synchronously, to avoid breakage of the cotton layer stretch.

8. Adopt man-machine interface for parameter setting and input of process data.

9. Abnormal fault alarm automatically.

10. Output bottom curtain width is detected automatically.

| Model NO. | HYPW |

| Certification | CE, ISO9001:2000 |

| Condition | New |

| Raw Material | Polyester Fiber, PP Staple Fiber, etc. |

| Output Apron Width | 3000mm~7000mm |

| Power(W) | 24W |

| Configuration | Can Be Customized According to Customer Needs |

| Mainly Application | Nonwoven Fabric |

| Transport Package | Nude Packing or PE Film |

| Trademark | HONGE |

| HS Code | 8449009000 |