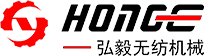

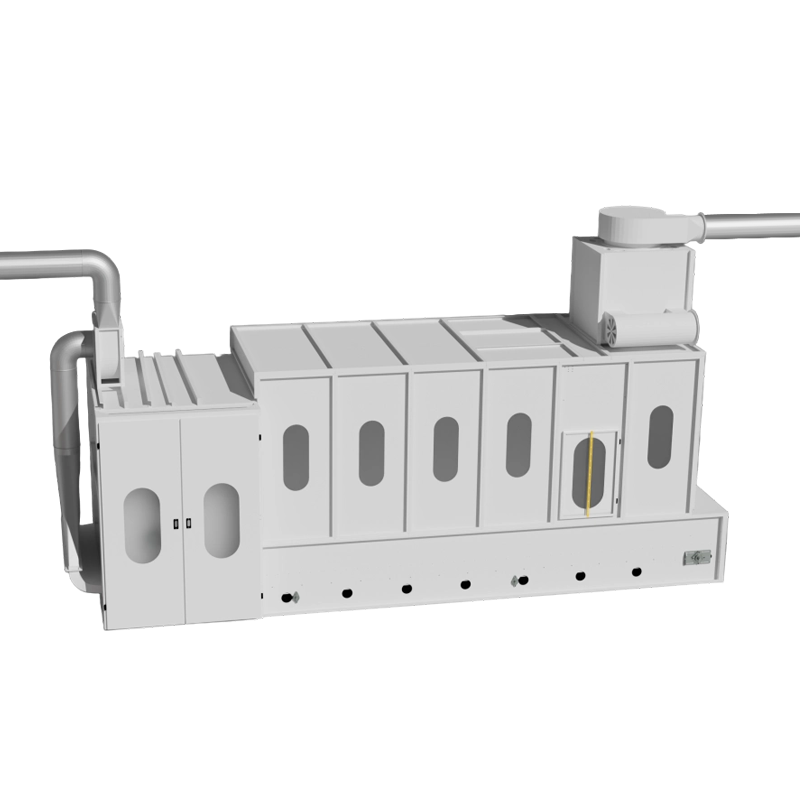

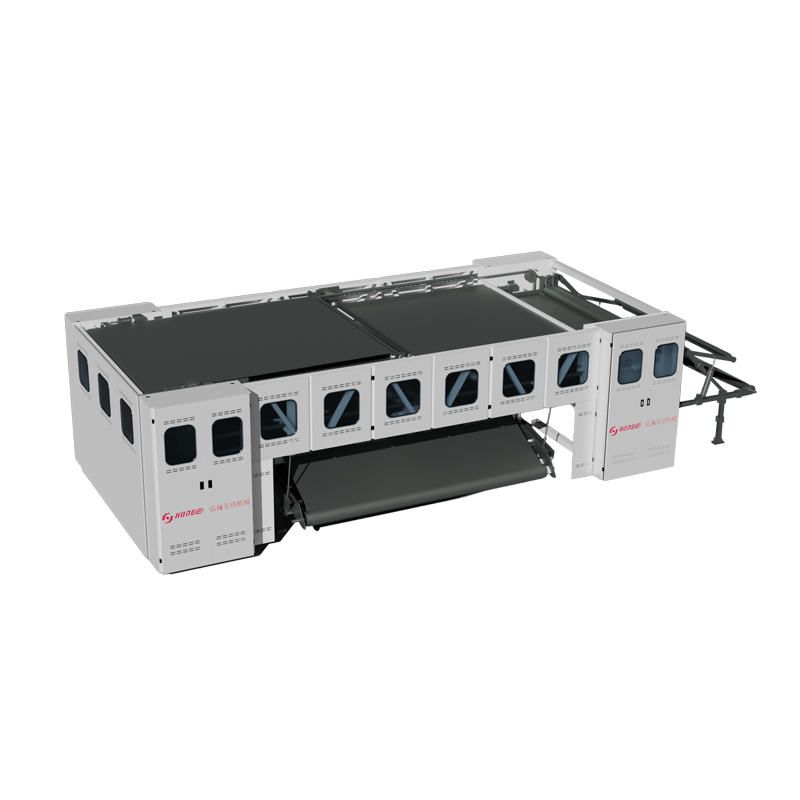

This pneumatic feeder is used to mix fiber and store the opened fiber ,then create an even fiber web layer into next working procedure,such as carding machine or for direct fiber web formation to feed ovens or other bonding systems.

The air-pressure feeding assures an high accuracy in cross section, and then an homogeneous fiber web formation.

Function:

After opening and blending machine, the fibers are fed into an even layer or batt to feed to the carding machine.

The pressure feeding assures an high accuracy in cross section, and then an homogeneous fiber web formation.

It can be used as a card feeding system.

The machine can be equipped with a belt weigher to better control weight in cross and longitudinal direction.

The machine can manage long, short, virgin and recycled fibers.

The pneumatic forming units gives top performances in web cross regulaity. For this reason, it is suitable to feed top performance card machines which require strict tolerances in terms of weight and productivity.

The belt weighing system is a further guarantee for longitudinal stability in term of weight.

Characteristics:

1. Upper and bottom chamber with built-in fan by variable speed inverter control. Completely sealed and pressurized air controlled system.

2. Fiber feeding by air-flow guiding and the feeding time is adjustable.

3. Highly accurate pneumatic control system with adjustable pressure.

4. Thickness of output fiber web is adjustable as needed.

5. Output feeding rollers are controlled by inventer.