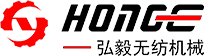

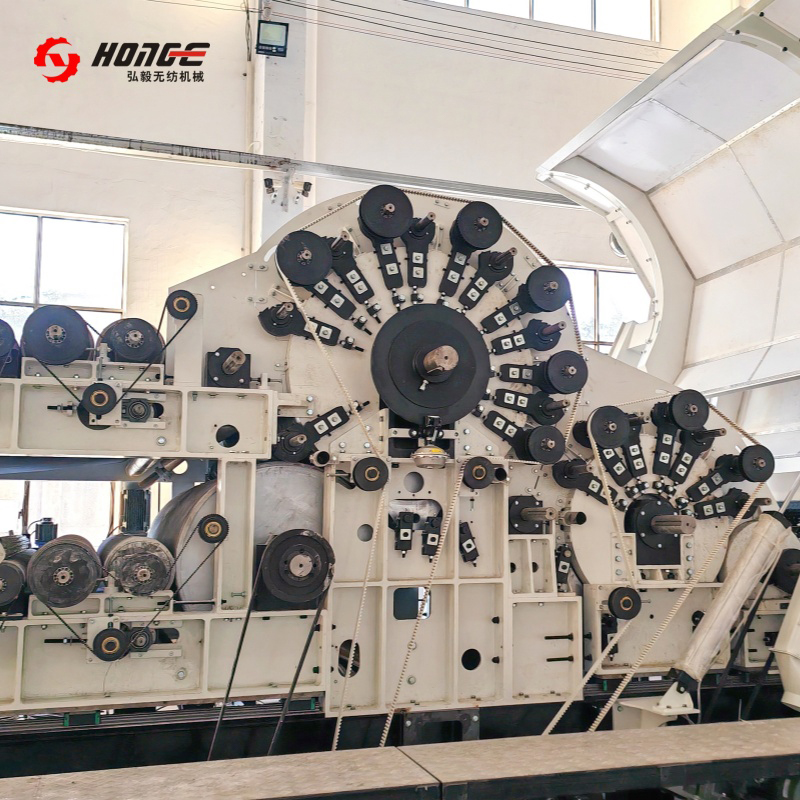

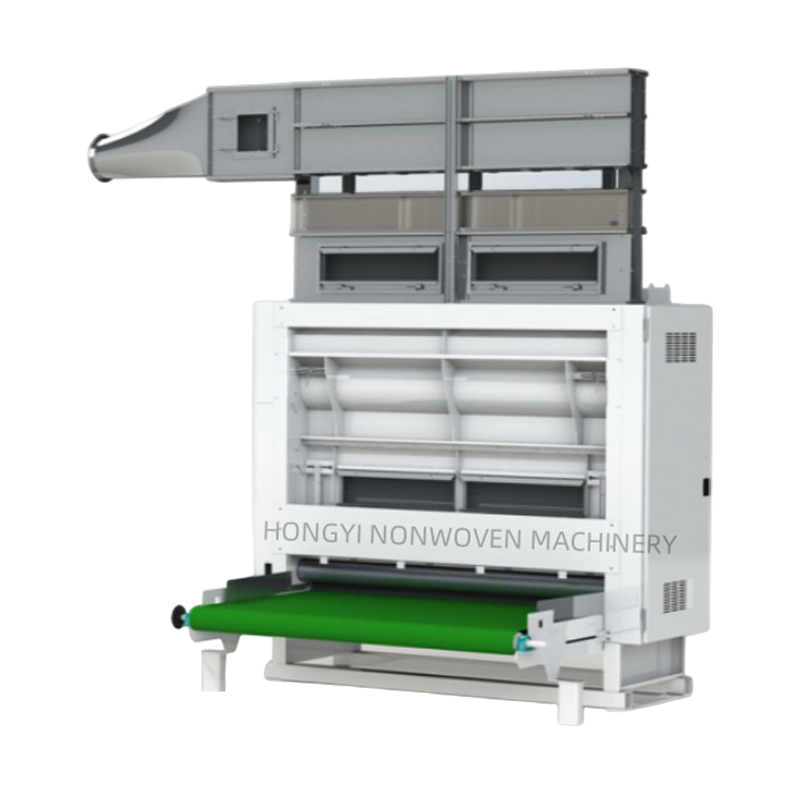

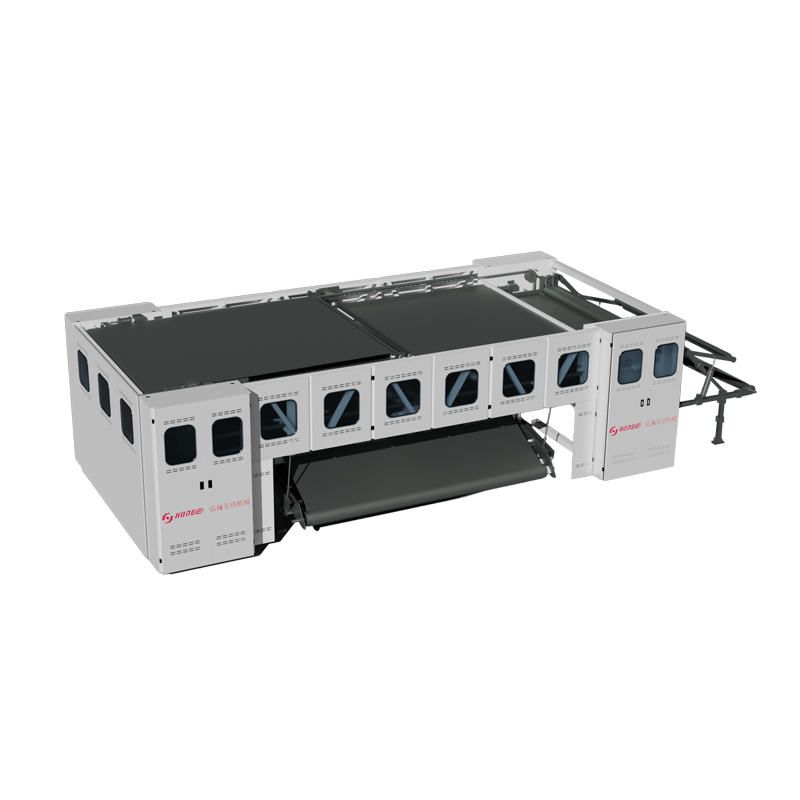

This machine is used for fully carding the fiber batt following opening and blending,then forming parallel or random web through doffer and random if required,which is then supplied to the next processes.

Characteristics:

Carding machine is very important solution for fiber process.

To meet different needs, the single-cylinder or double-cylinder structure is all available.

Also different capacity is applicable depend on different working width and sizes.

All types of carding machine,both single and double doffers can be fitted with randomizer rollers or not dependent on customer's needs.

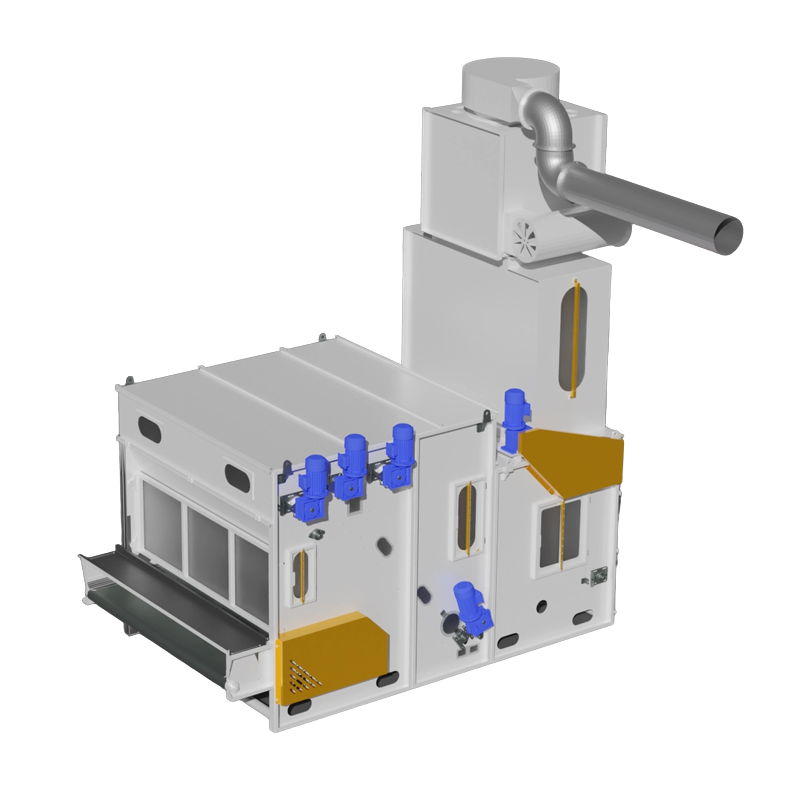

All drives including main drive,doffers,working rollers,feeding rollers ect. are variable speed.Metal detection devices are standard on feeding rollers.

Carding wires can be supplied as surface wound or interlocking as required.

All main cylinders and large rollers are precisely balanced prior to assembly.

The control system may be by servo-motor or inverter drives according to customer requirements.This ensures that the total production line will have constant synchronization with controlled stable start and stop.

Carding machine is fitted with a system to minimize rollers of fiber thus helping to protect carding wire.

The carding machine has a complete and total electronic safety system to meet all international standards.

Other details and variables are dependent on customer's needs and can be discussed with our technical staff.

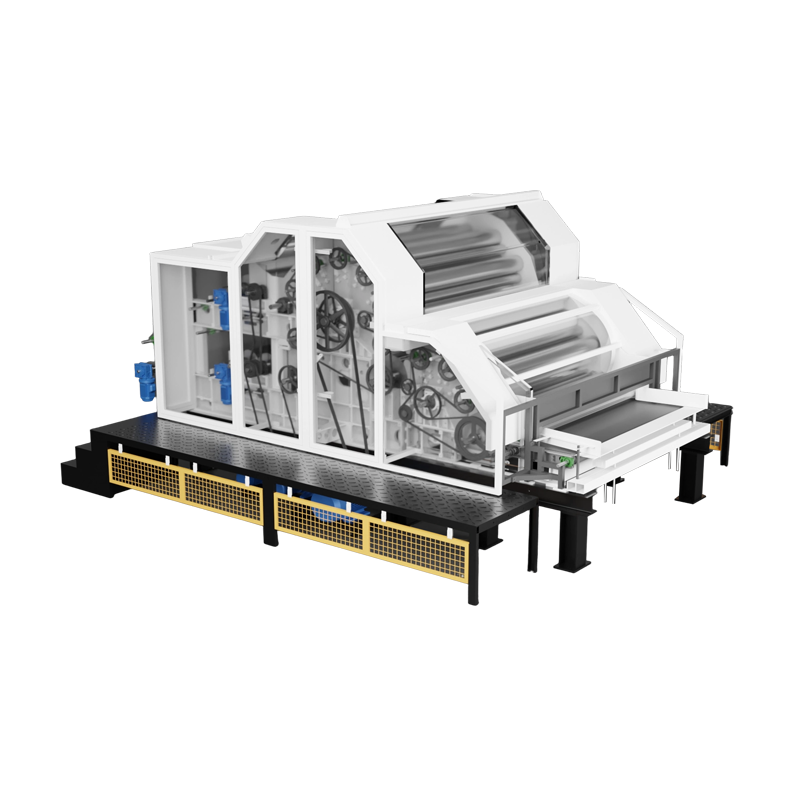

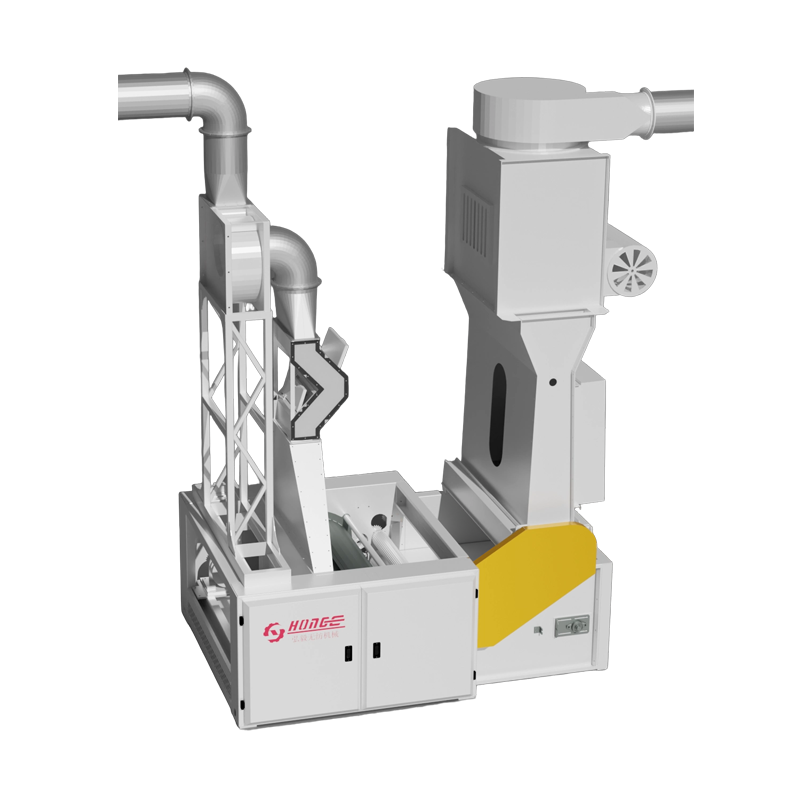

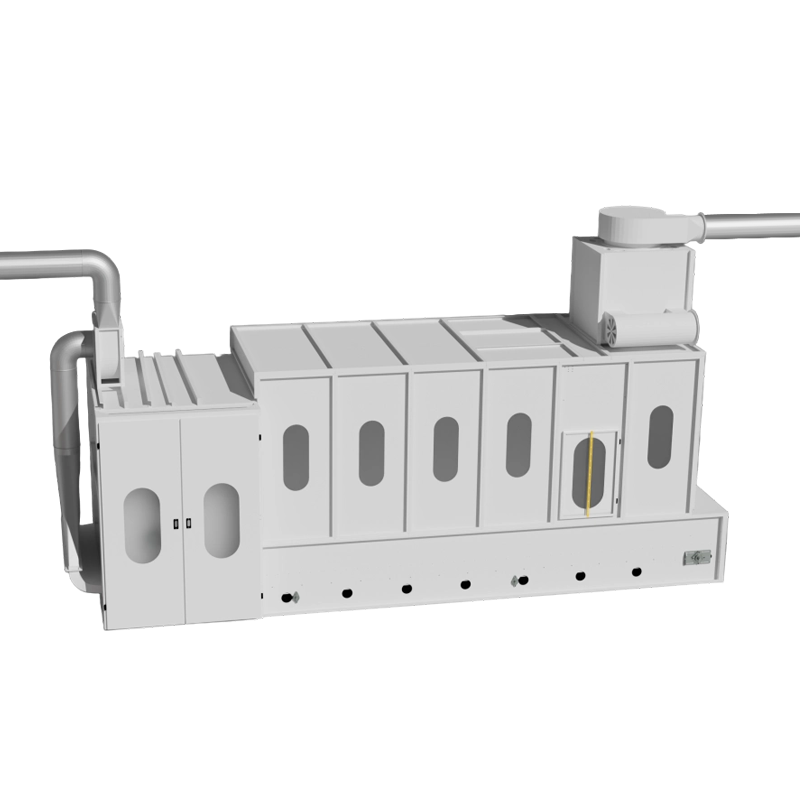

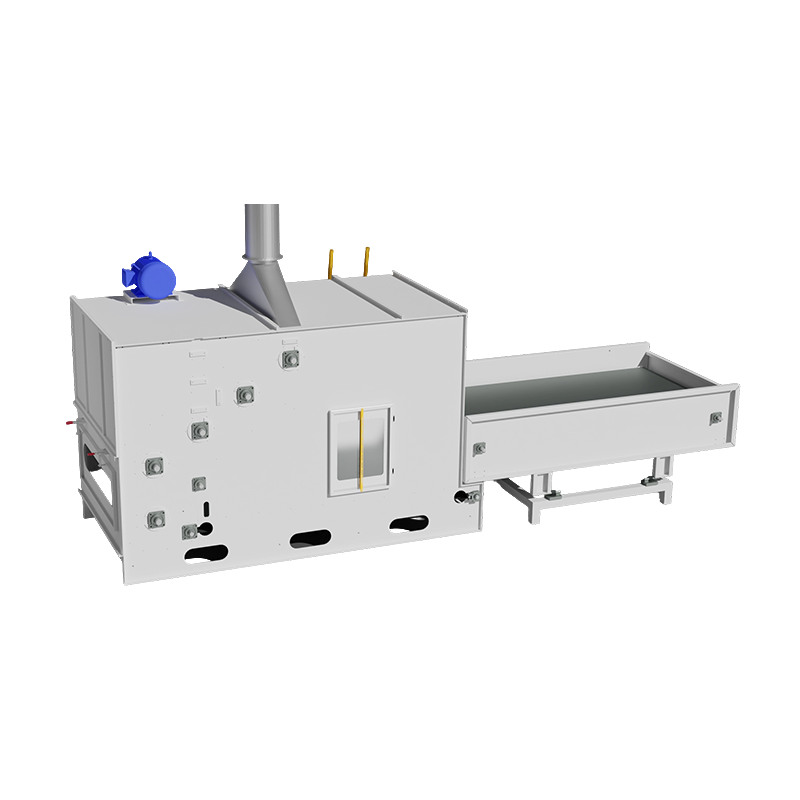

Structure:

1. Horizontal feeding lattice is PVC lattice, with pressing roller for evenly feeding.

2. Four rollers for feeding with diameter 90mm, anti-metal protection device is used at the input part of the machine, which could test the metal and has auto-stop warning.

3. There are five suits of working roller and stripping roller on main cylinder to card fiber completely and form web evenly.

4. Edge-suction system is equipped and the dust particles will be transferred to special dust cage.

5. Walking platforms are placed on two sides of machine for maintenance.

6. Machine safe guard cover is transparent organic glass.

7. Carding wire is high quality from GERON.

| Model NO. | HYSL |

| Certification | CE, ISO9001:2000 |

| Condition | New |

| Working Width | 1.55m/1.85m/2m/2.5m/2.8m |

| Power(W) | 24W |

| Raw Material | Pet Fiber, etc. |

| Brand | Hongyi |

| Transport Package | Nude Packing or PE Film |

| Trademark | HONGE |

| HS Code | 8449009000 |