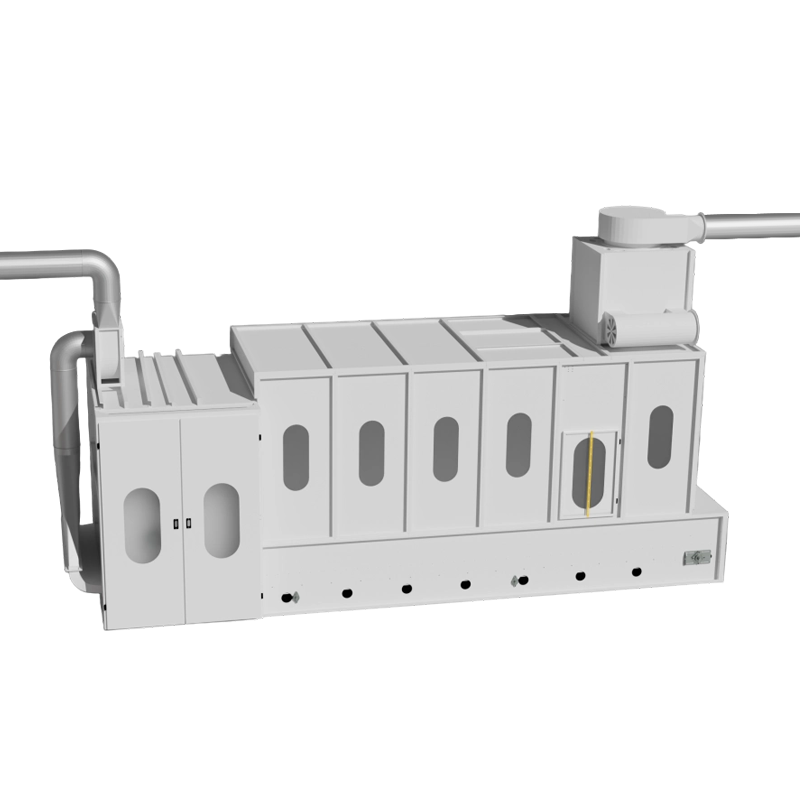

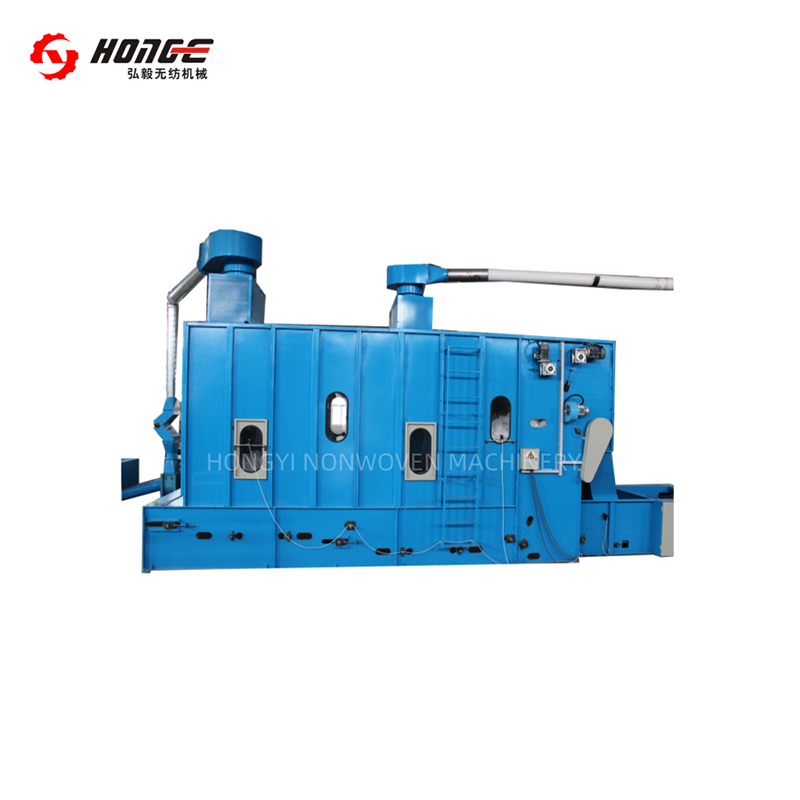

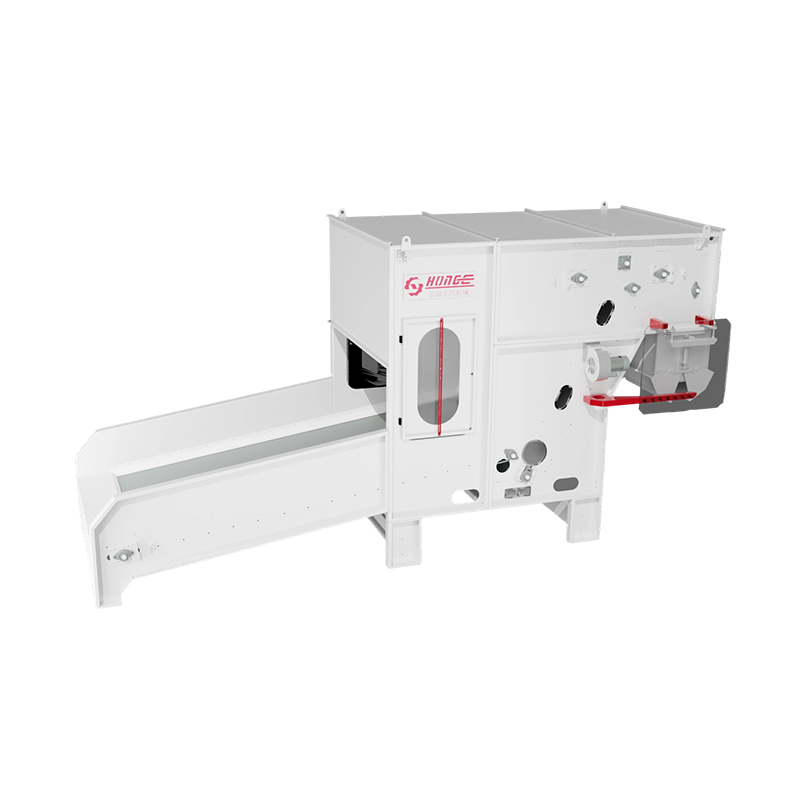

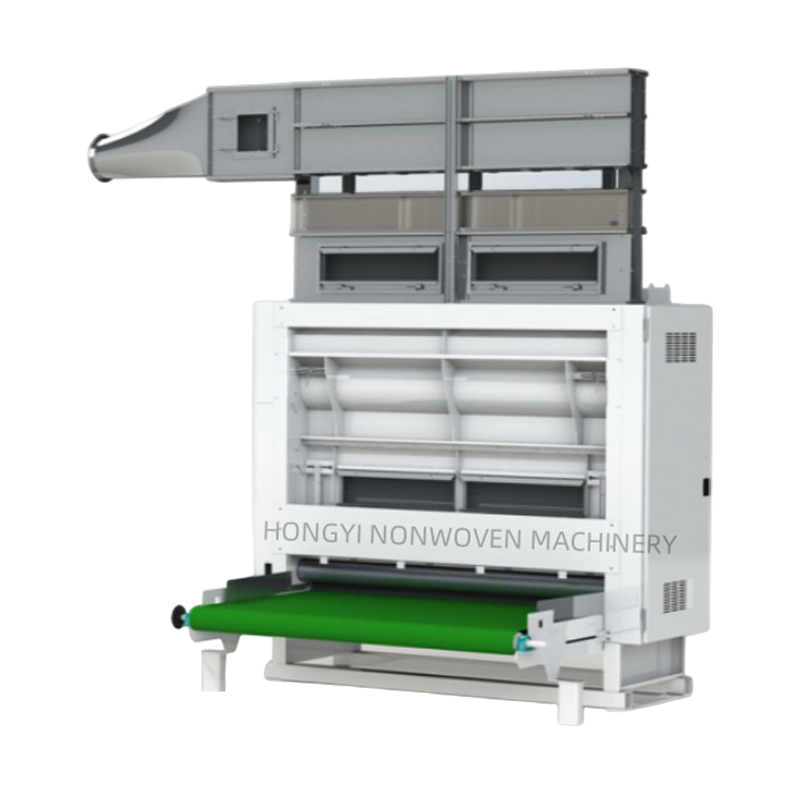

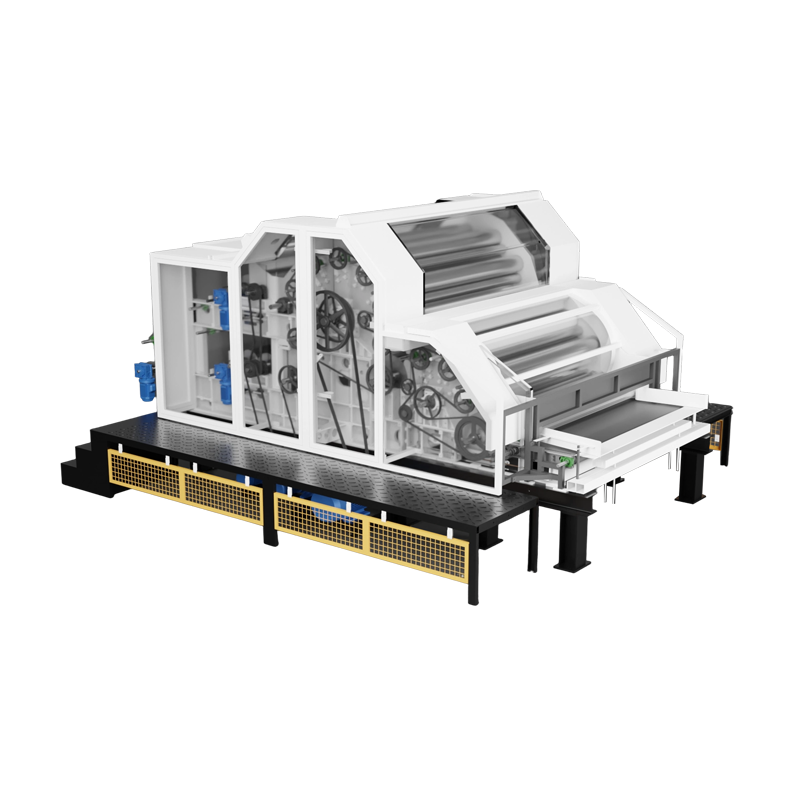

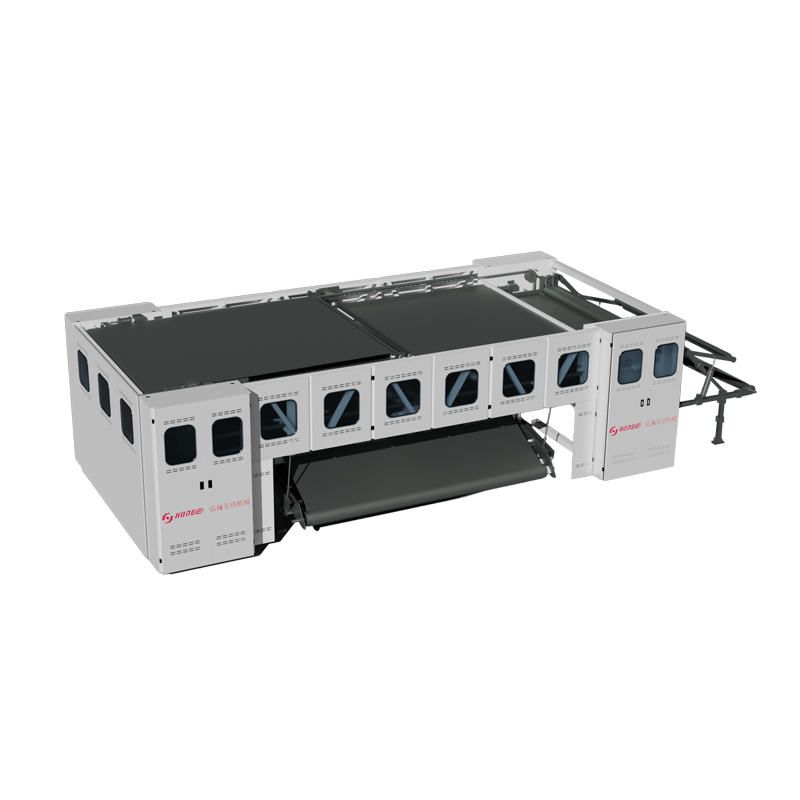

HYDC Big chamber blender is used to blend and store any opened fiber to also ensure continuous production feed to the card line. It can be used to deal with many kinds raw materials, such as polyester fiber, polypropylene staple fiber, wool, cotton, coir fiber, jute fiber, ES fiber, etc. The fiber can be mixed and stored in the cabinet for next procedure.

Structure:

1) Machine fram is several wall-boards welded by Q235-A armor plate, combined by bolts.

2) Horizontal delivery lattice is the anti-skidding leather belt, strengthened by many layer rollers in the center, and two sides are equipped with wooden batten.

3) The spike lattice is made of high quality wood with canvas interlining and surrounded with angle steel for supporting.

4) Rotary separator ensures the fiber distributed in the blending chamber evenly.

5) Two photoelectrical sensors control the feeding status.

6) A dodge gate is set at the end of the box, for cleaning the interior conveniently. It is also equipped with safety switch.

Features:

1. Photoelectric control during the production process.

2. Fiber density spreads even.

3. The stripper and evener roller are in the independent transmission. This will be with high dependability, easy adjustment and maintenance.

4. The spike lattice with the machine behind control the feeding by Photoelectric to make the blending evener.