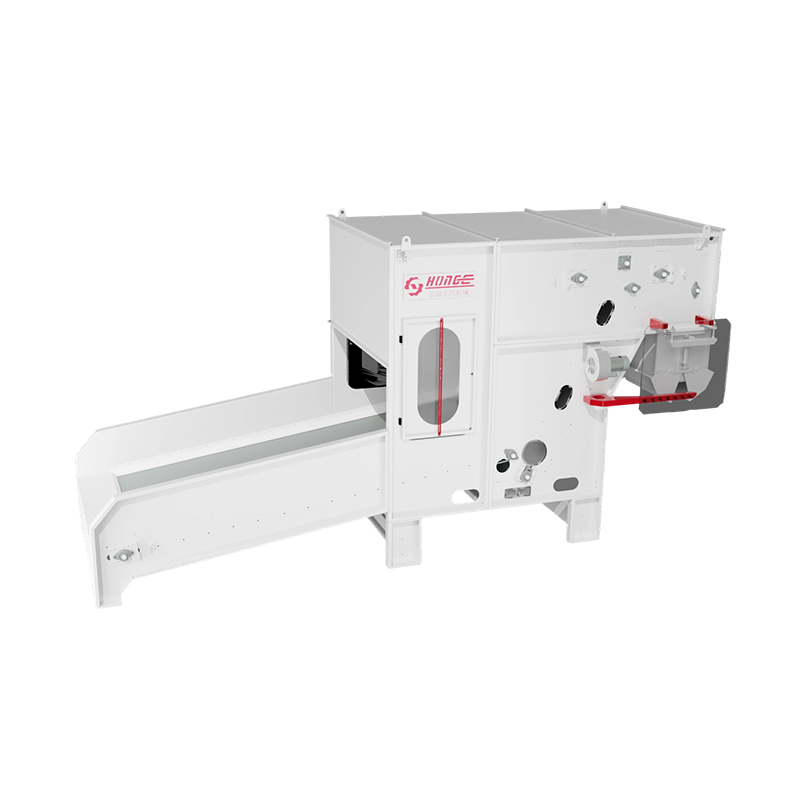

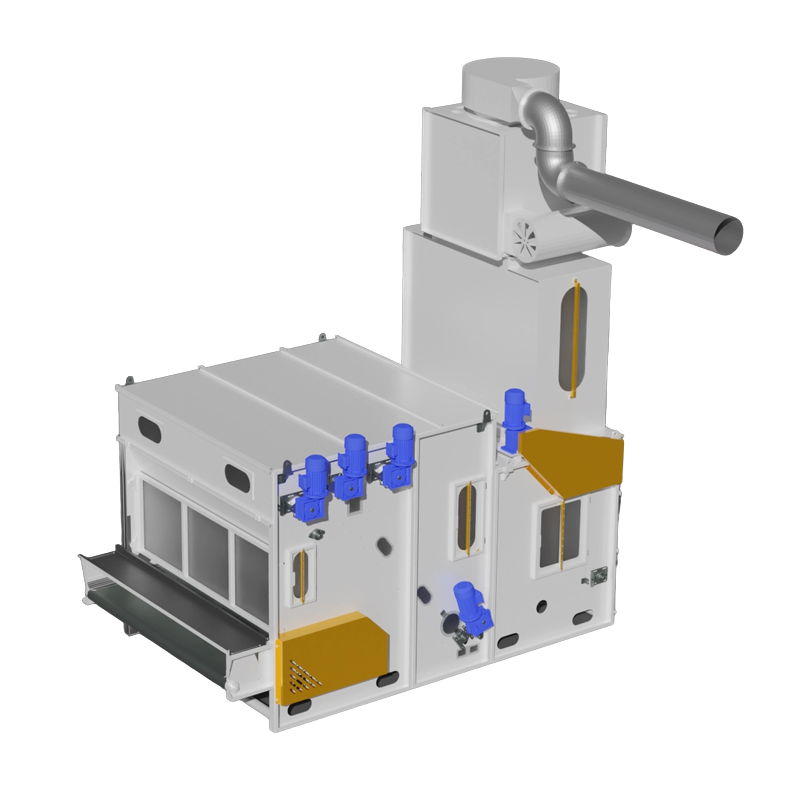

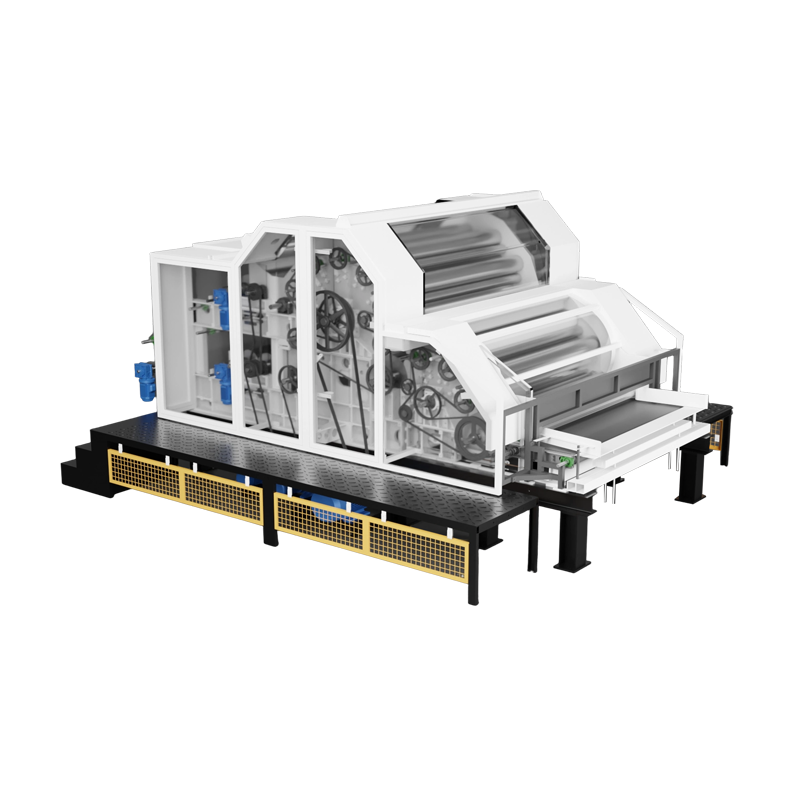

The airlaid technology is based on a new aerodynamic fiber batt formation system.

In many applications of the nonwoven sector,capable of replacing traditional mechanical processes using carding machine and cross lapper.

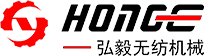

Machine description:

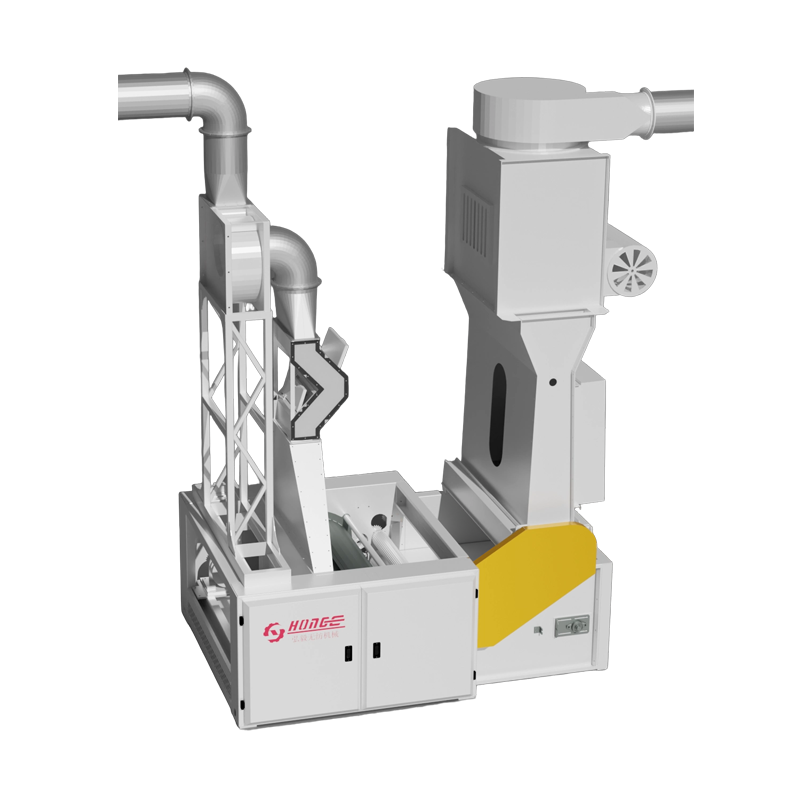

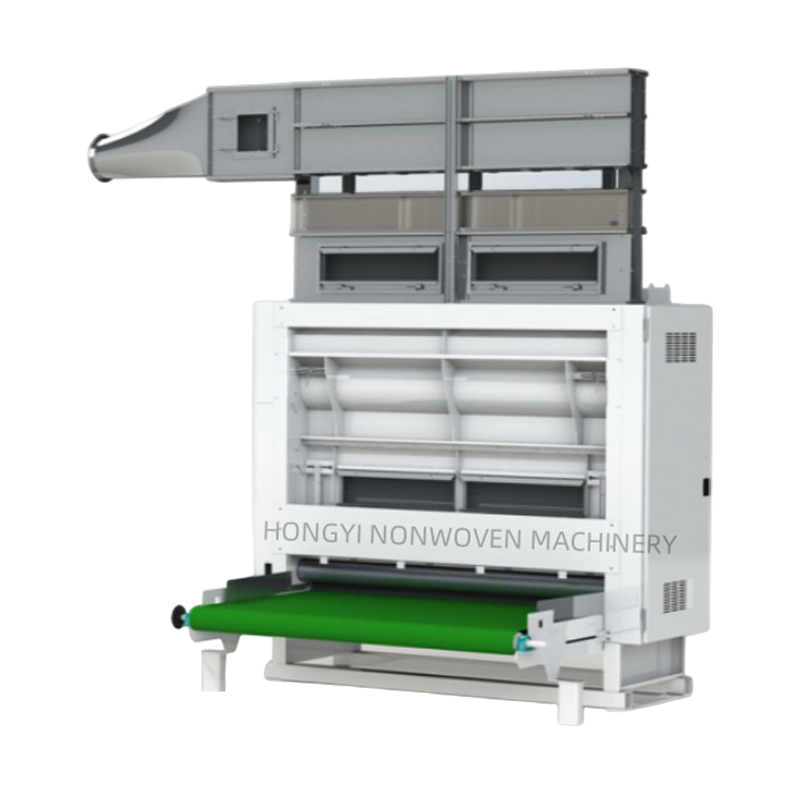

This air laid machine is the core equipment of thermal bonding wadding production line.

It takes place of normal formation by carding machine and cross lapper.

Suitable for shoddy fiber, crushed sponge, PET fiber,cotton,low melt fiber, wool, etc.

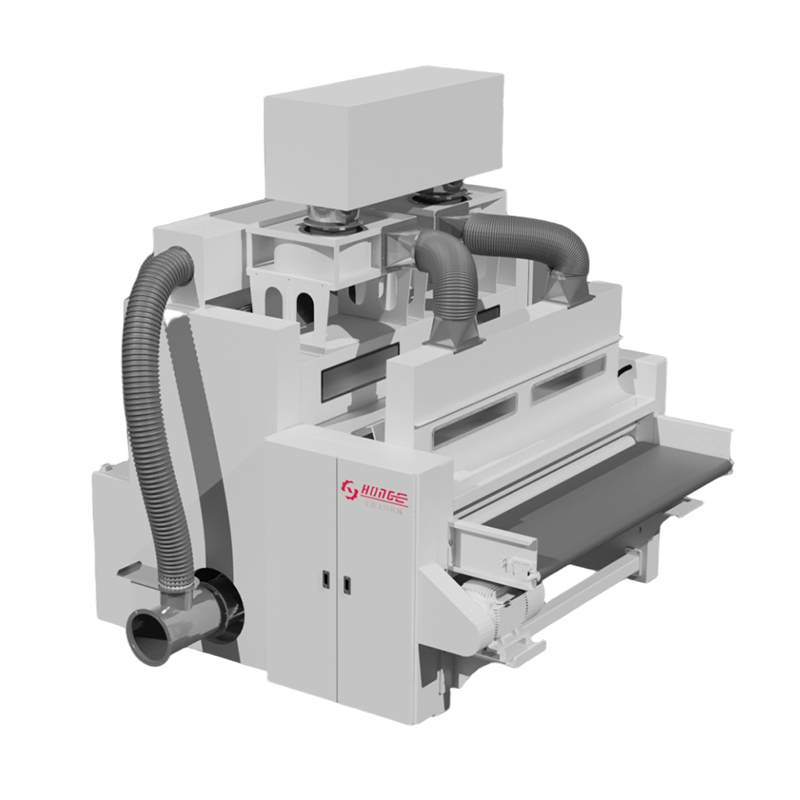

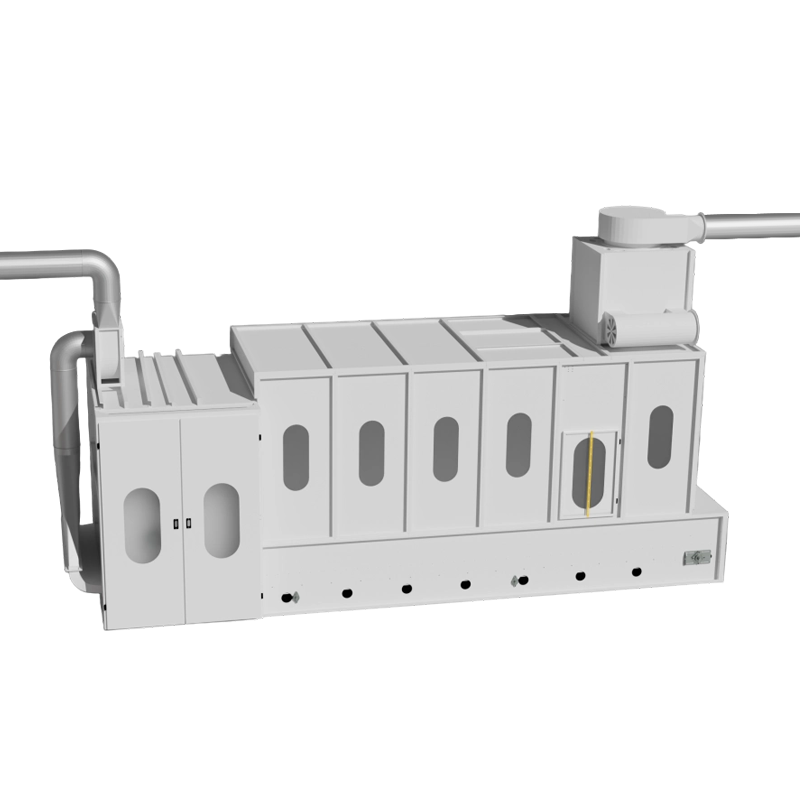

Making low melt fiber or bi-component fiber mixed with normal polyester fiber in properties to create stiff waddings, or such as foam replacements for quilts, cushion, mattress, acoustic and insulation materials, etc.

Also able to make soft wadding for interlinings such as home textiles, garments, furniture, toys, etc.

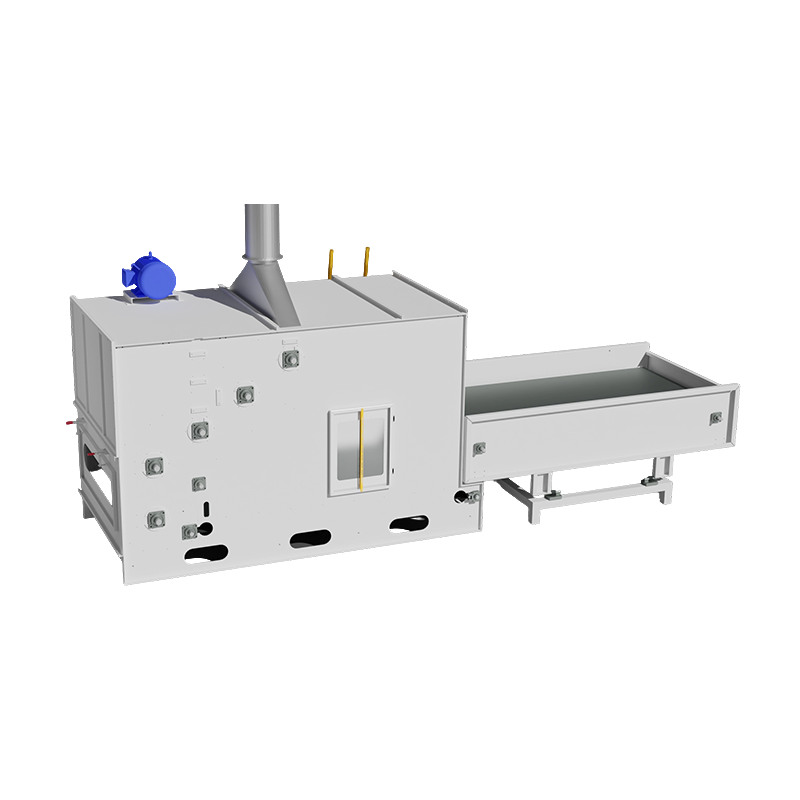

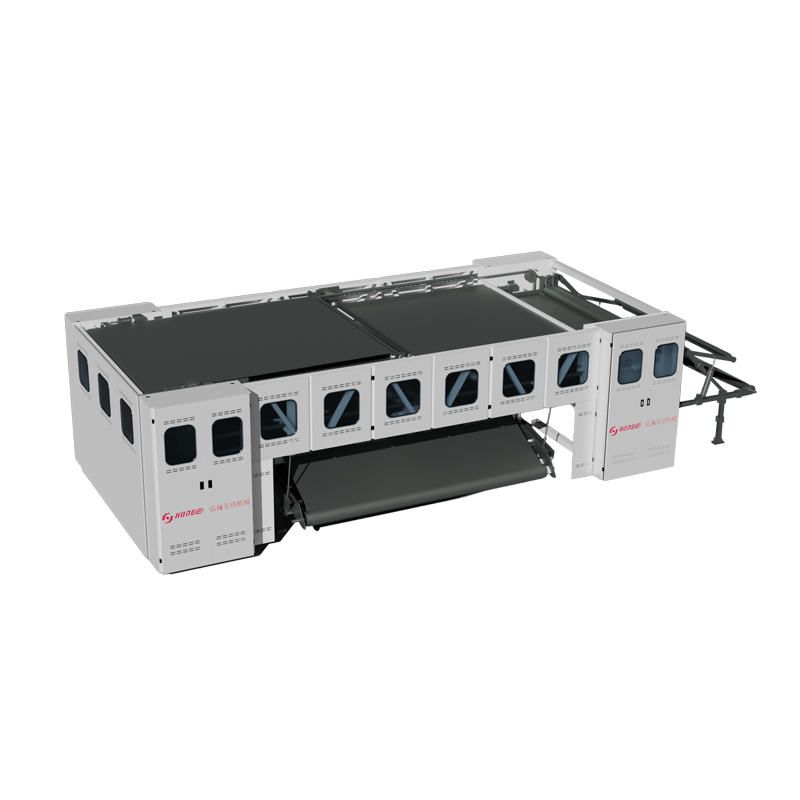

The material after forming into a batt is passed through a thermal-bonded oven with stainless steel or belt dependent on the products where fitted the top belt is a movable compression belt.

However, for soft waddings, eg. lofty material below 1500gram per square meter. It is normal to use belts for the oven machine.