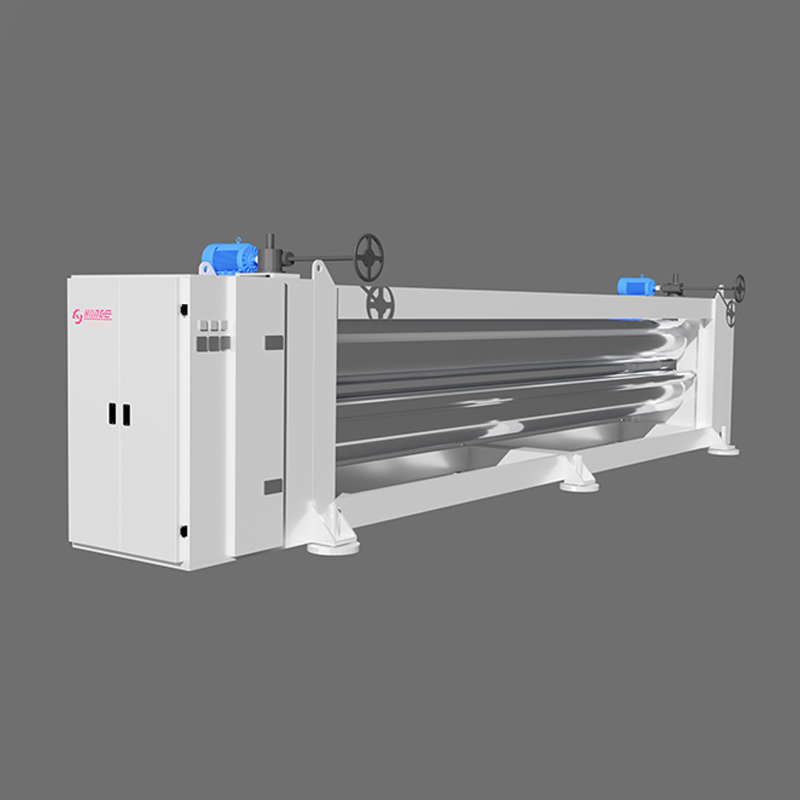

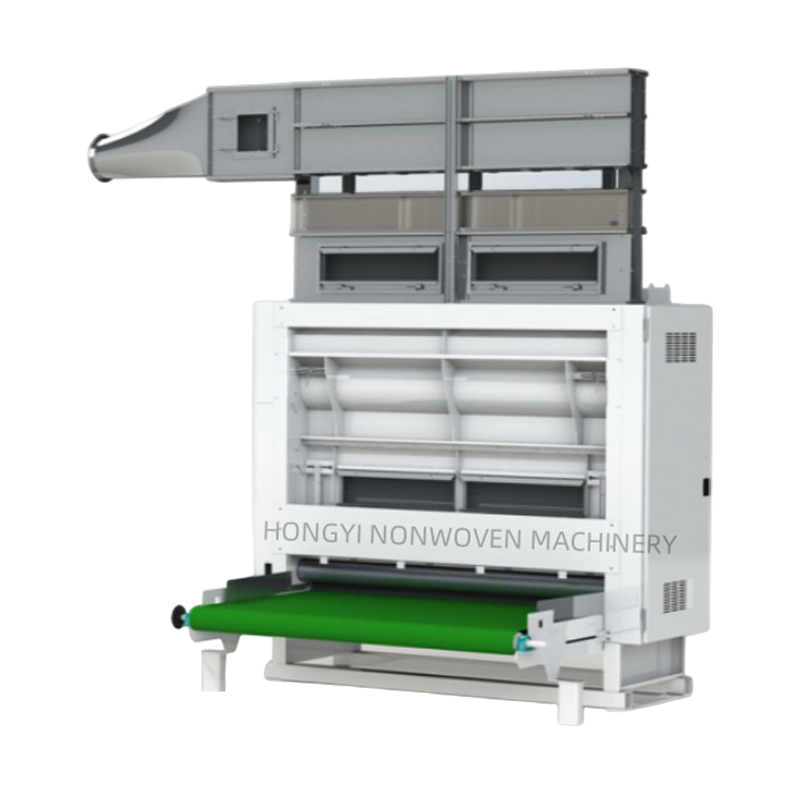

The nonwoven machine is used to heat pressing on the needle punched fabric to make the surface flat,neat and it is also used for after-treatment to make nonwovens' surface smooth, improve hand feeling and luster.

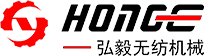

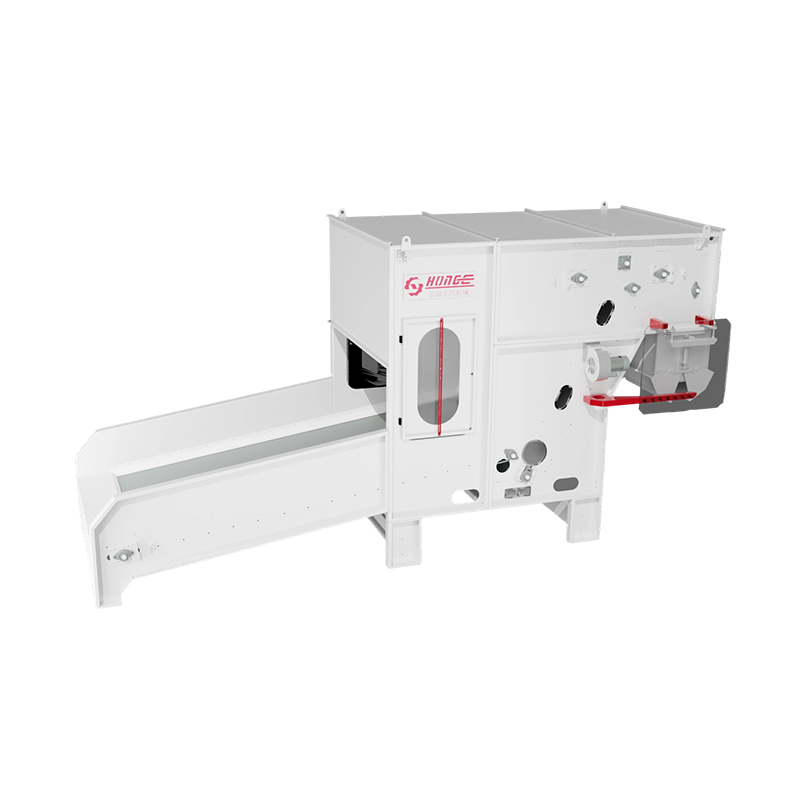

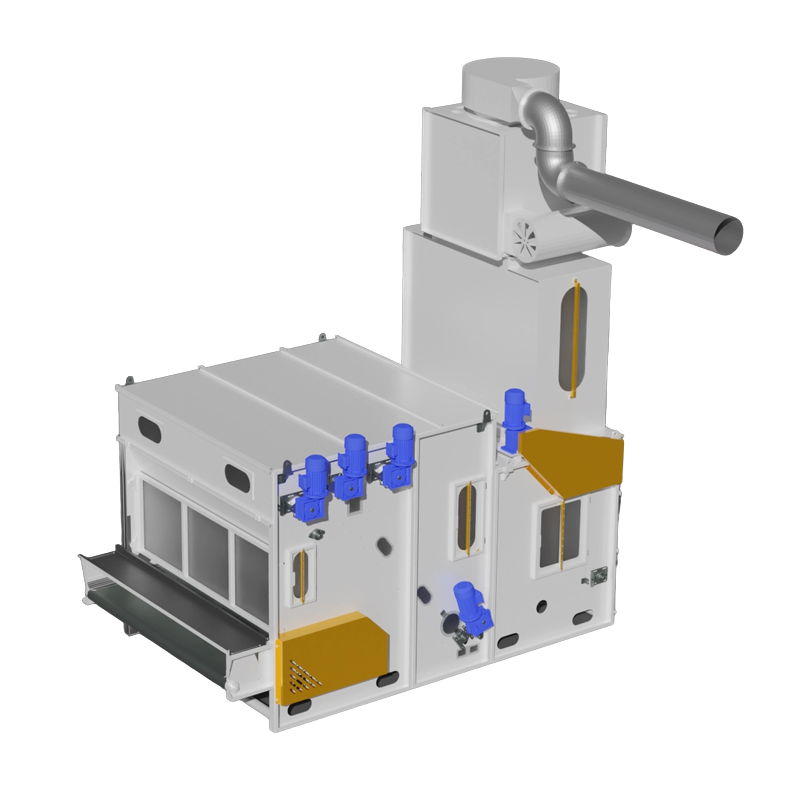

Structure:

It is made up of machine frame, ironing roller, electric heating tube, and driving system.

Heated rollers are made of heat resistant alloy steel with surface coated chrome, and the gap among rollers is adjustable.

Inverter motor is used for drive and control.

Operation principle:

Two ironing rollers heat up the heat-conducting oil by electric heating tube, and the heat-conducting oil transfers the heat to the working surface of rollers evenly to make the passing nonwoven web ironed and formed.

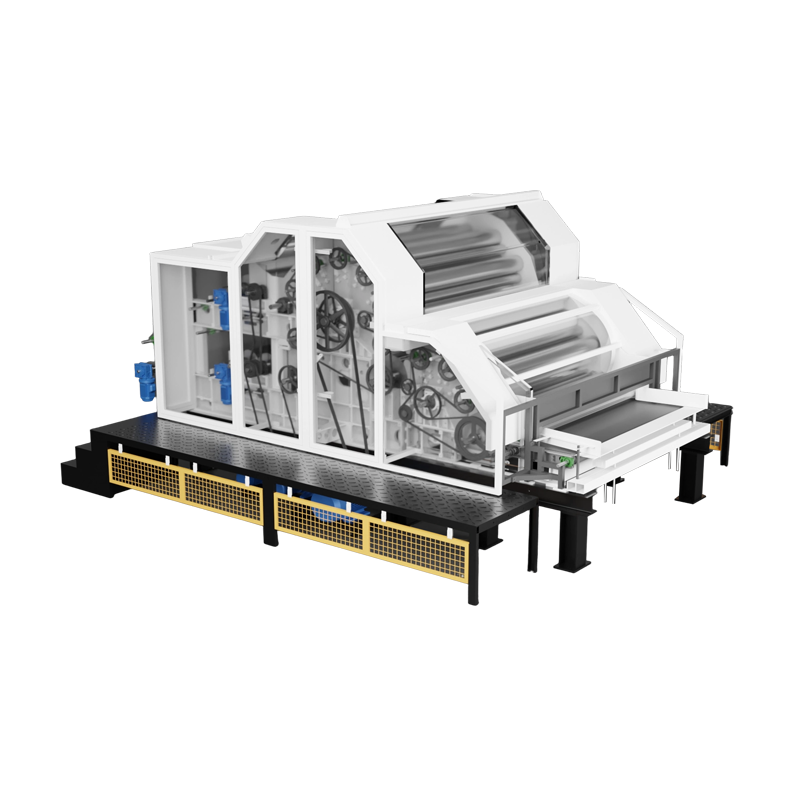

1.High quality welded armor plate is made into machine frame.

2.Hot pressing roller chrome plating 0.1mm; Smooth surface finish reaches V12 level.

3.Two-roller vertical type, with heat conductive oil heated by electricity.

4.The distance between two rollers can be adjusted electrically, the distance range is ≤50mm.

5.Temperature of three rollers is controlled separately, automatically constant temperature.

6.The machine is with protective guide plate, and brake safety rope device.

| Model NO. | HYTG |

| Certification | CE, ISO9001:2000 |

| Condition | New |

| Voltage | 220 or Customized |

| Video Outgoing-Inspection | Provided |

| Colour | Can Be Customized According to Customer Needs |

| Lead Time | 2-3 Months |

| Working Width | 2000mm-7600mm |

| Heating Methods | Hot Oil Circulation, Electricity Heating |

| Transport Package | Nude Packing or PE Film |

| Trademark | HONGE |

| HS Code | 8449009000 |