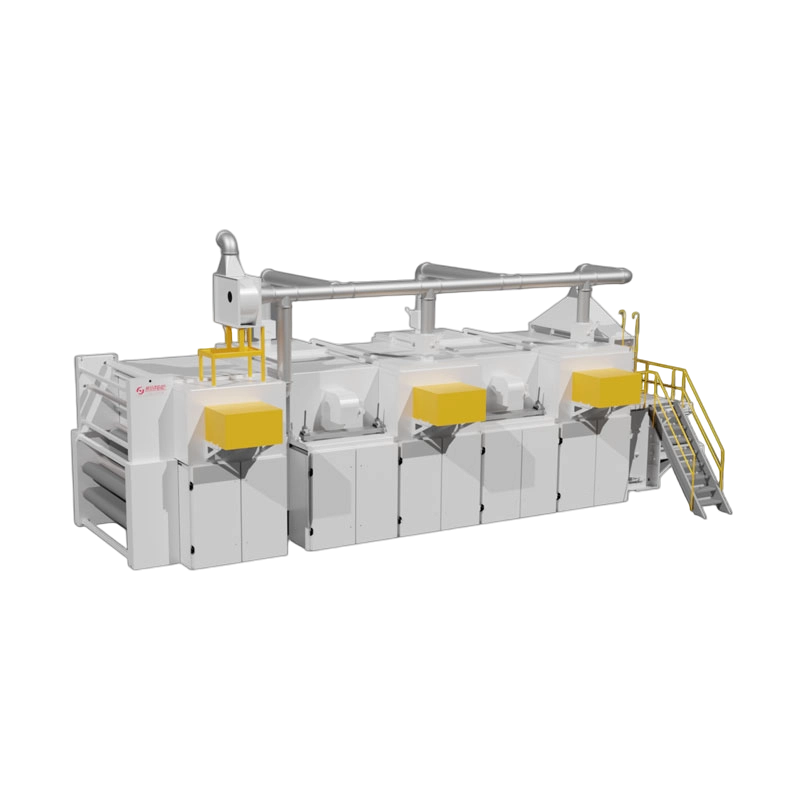

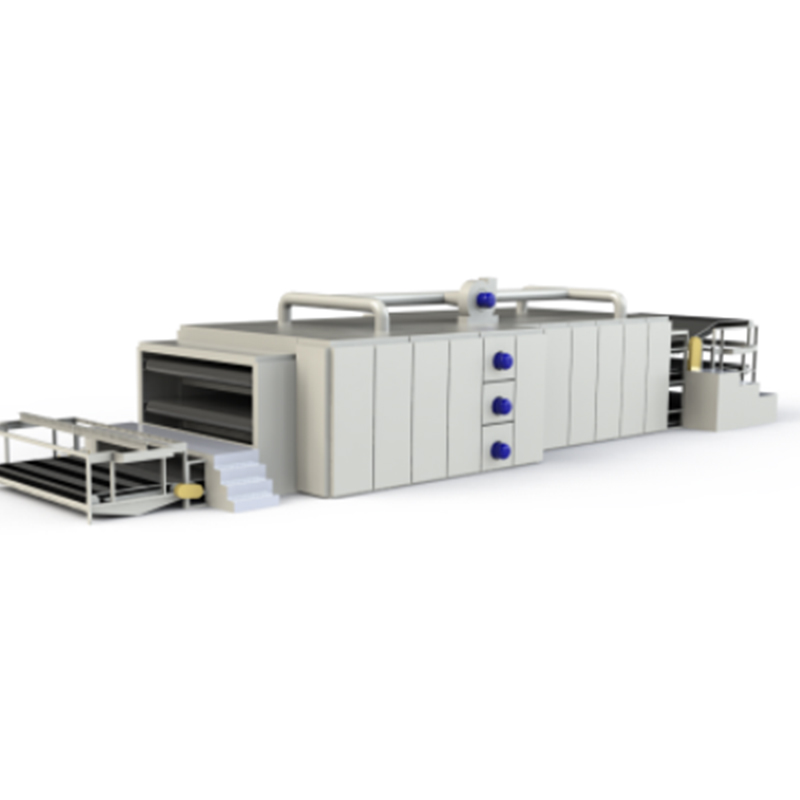

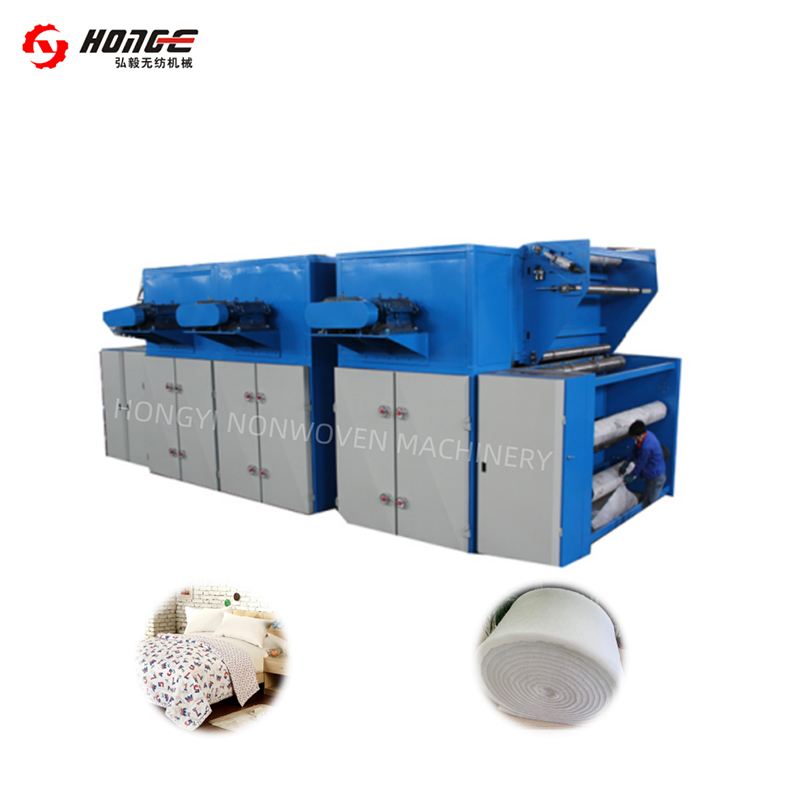

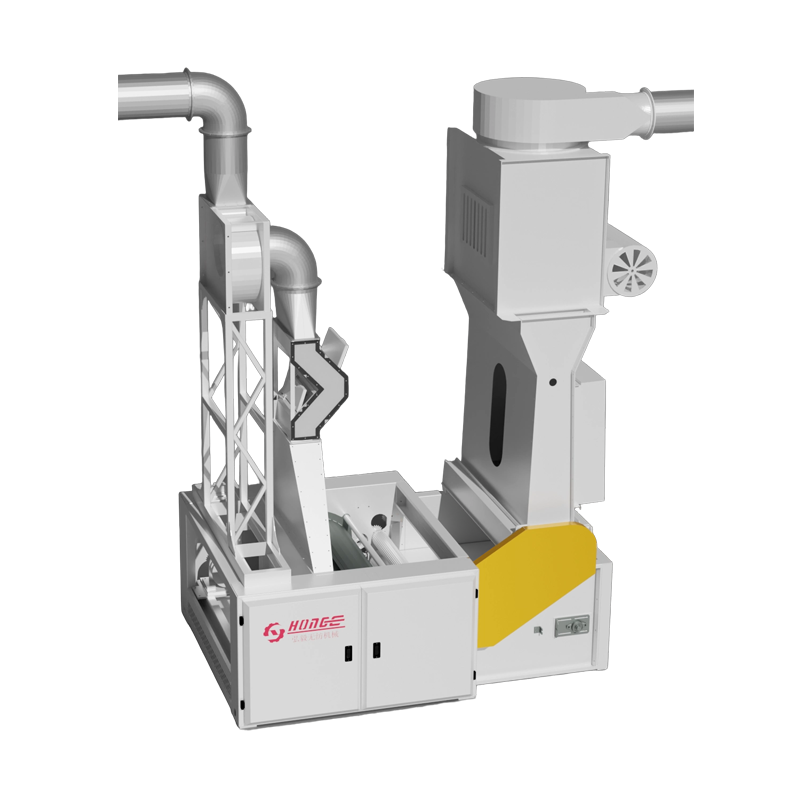

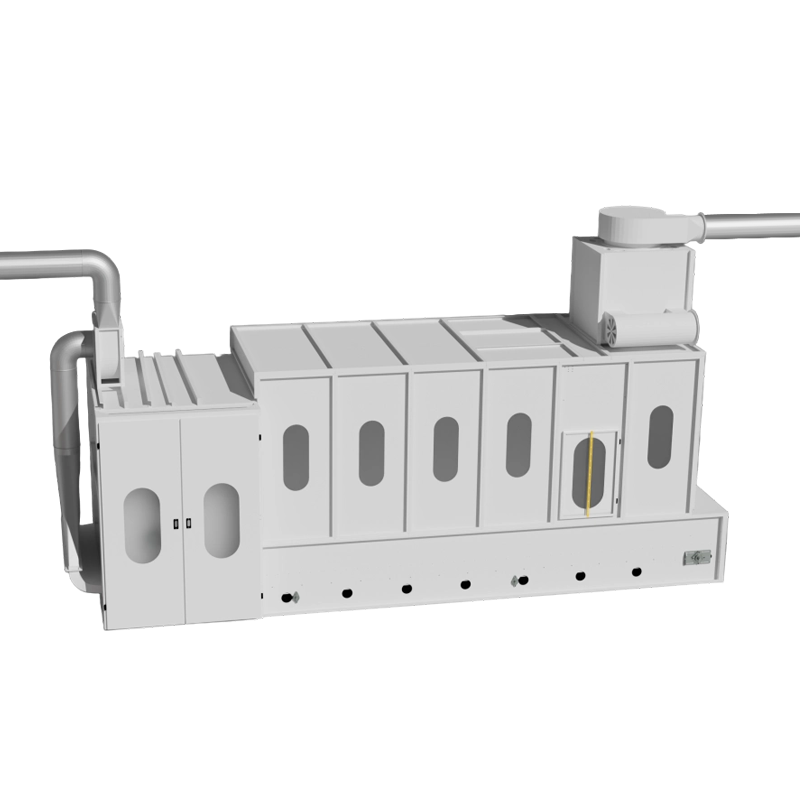

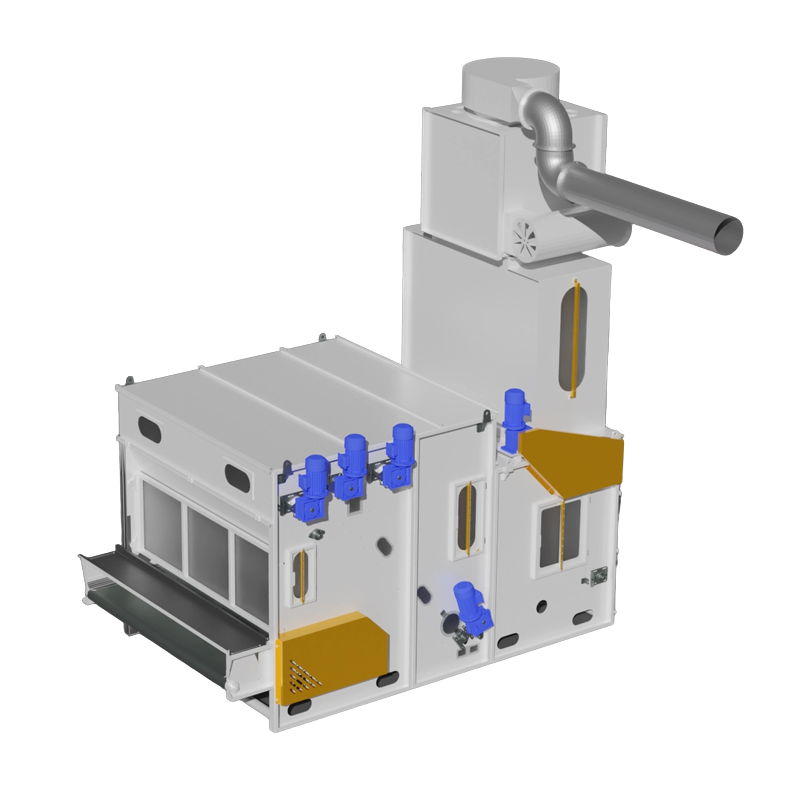

This machine is used to thermal bond the web from cross lapper by melting the low melt fiber by hot air penetration.

Function

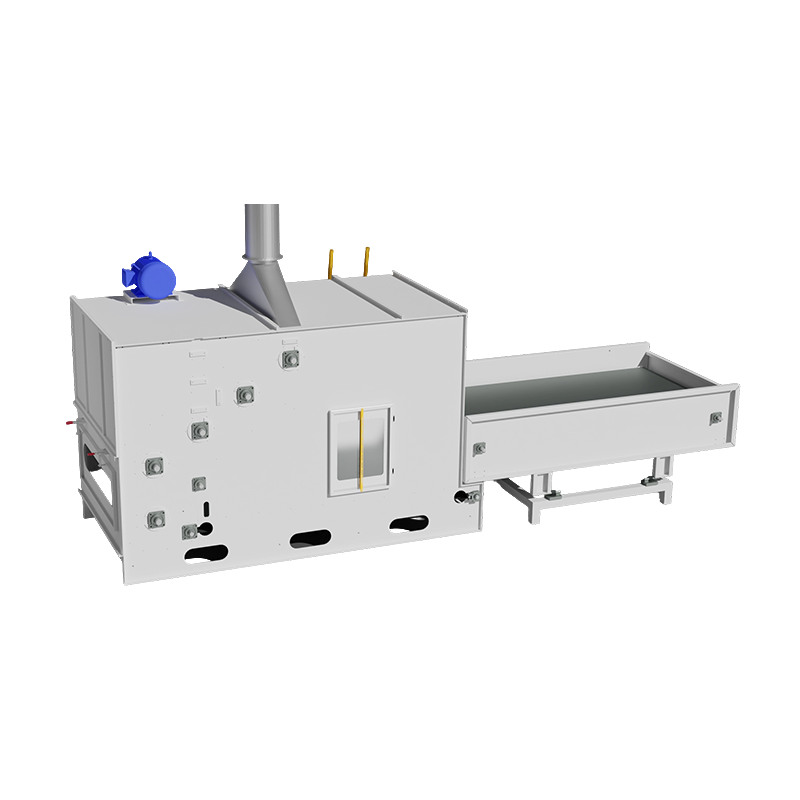

The machine is used to process the batt of fiber to obtain a hard and thick thermal-bonding wadding.The low melt fiber will combine other fibers together through hot air penetration and colling system for reinforcement.

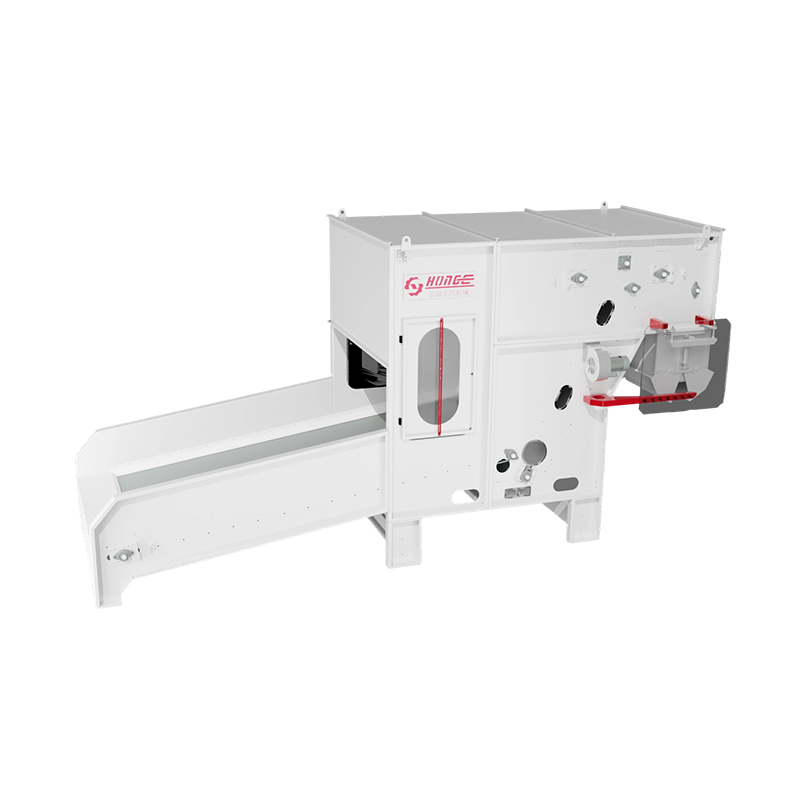

Structure

-Single layer,single belt or double-belt structure

-Up and down belts hold the web for entering to get heated and formed.

-High temperrature resistance belt with auto correction device.

-Main drive and fan inverter controlling.