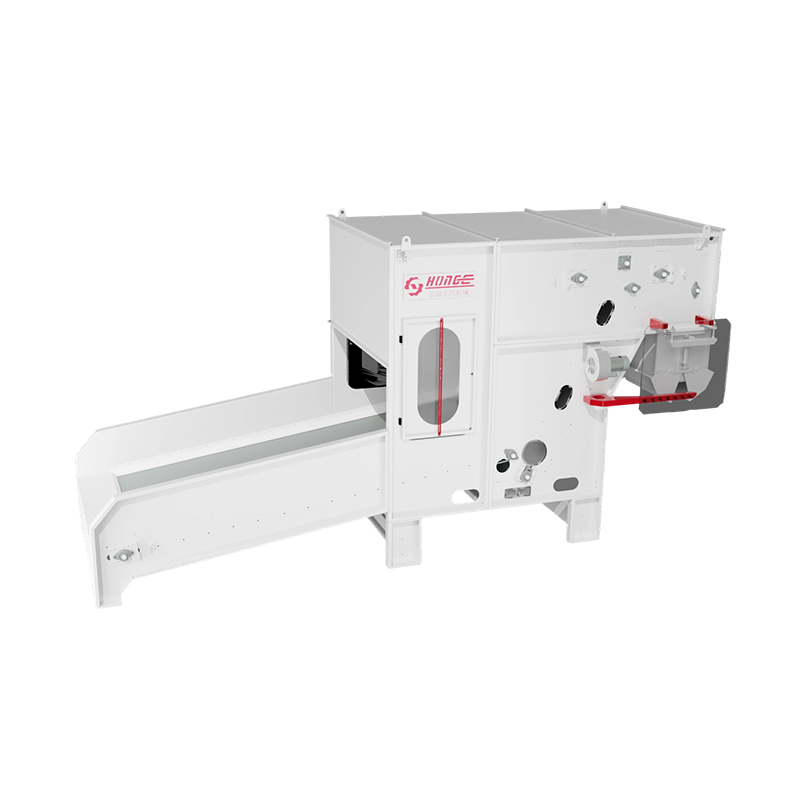

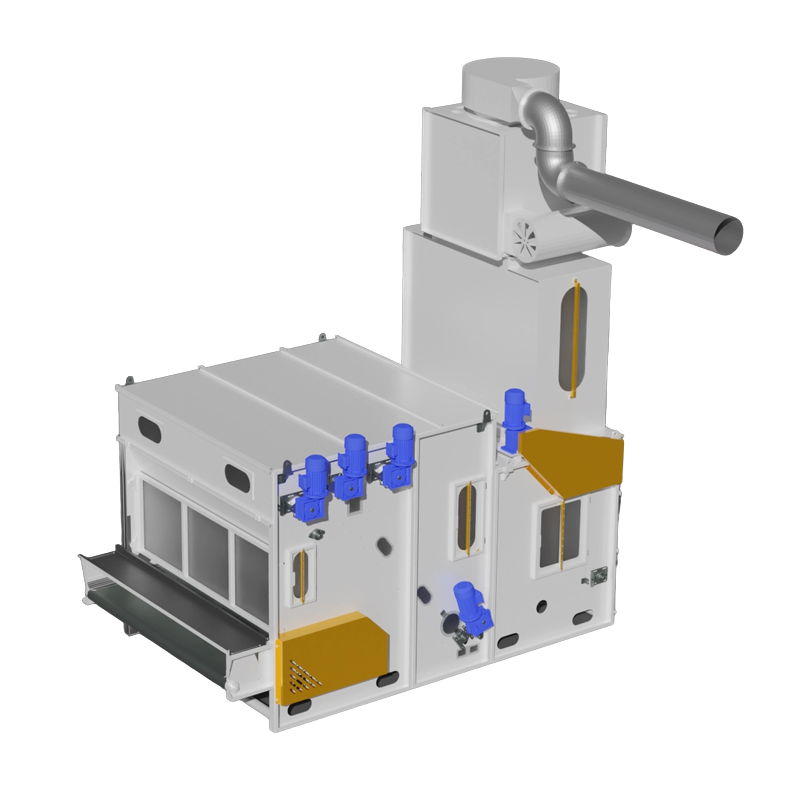

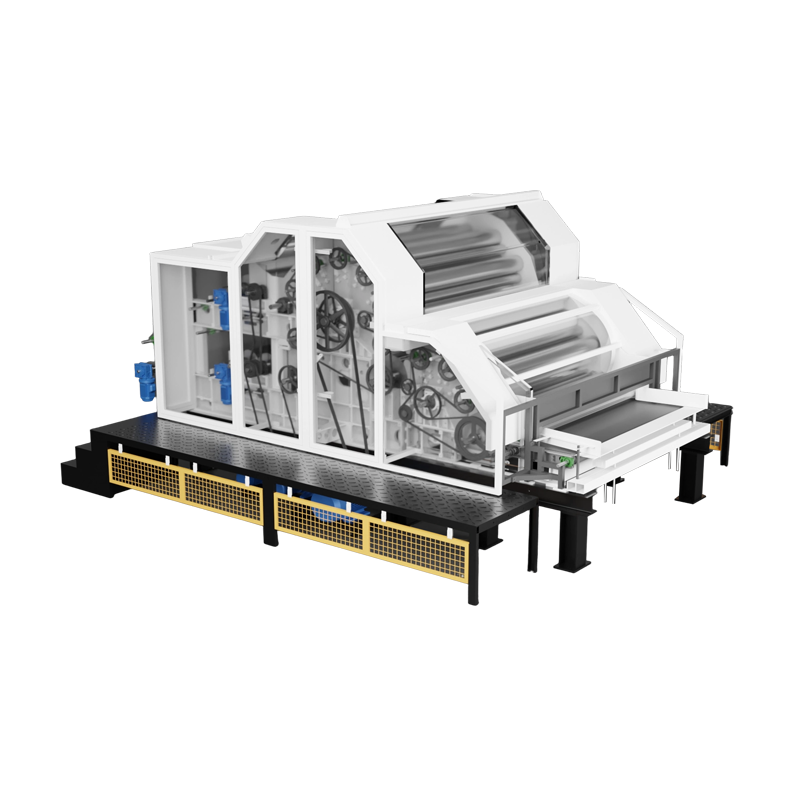

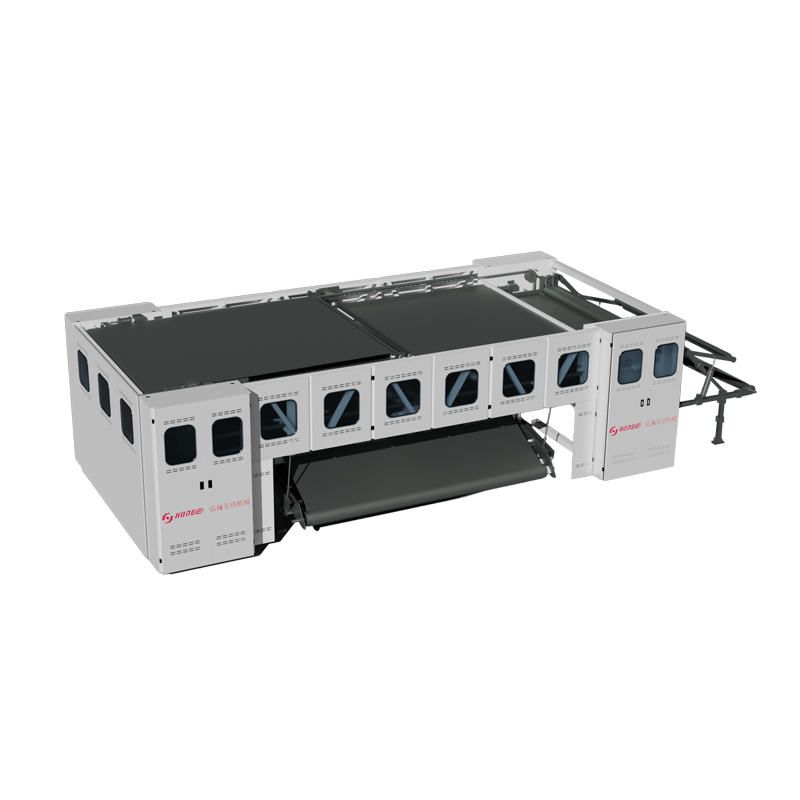

The HYYQ Pre-Edge Cutting Device is a specialized machine for pre-processing the edges of fiber webs. Through an independent and precise edge pre-cutting process, it accurately and consistently pre-cuts the edges of the fiber webs according to pre-set data to obtain the required width, preparing the web for the next processing step.

Product Features and Advantages:

Dedicated pre-processing design ensures edge processing accuracy

Optimized cutting process improves edge flatness and consistency

Easy to integrate into automated production lines for continuous operation

Precision control system ensures accurate cutting dimensions

Suitable for various raw material fiber product

Modular design simplifies daily maintenance and tool replacement

Rugged structure ensures long-term stable operation