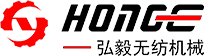

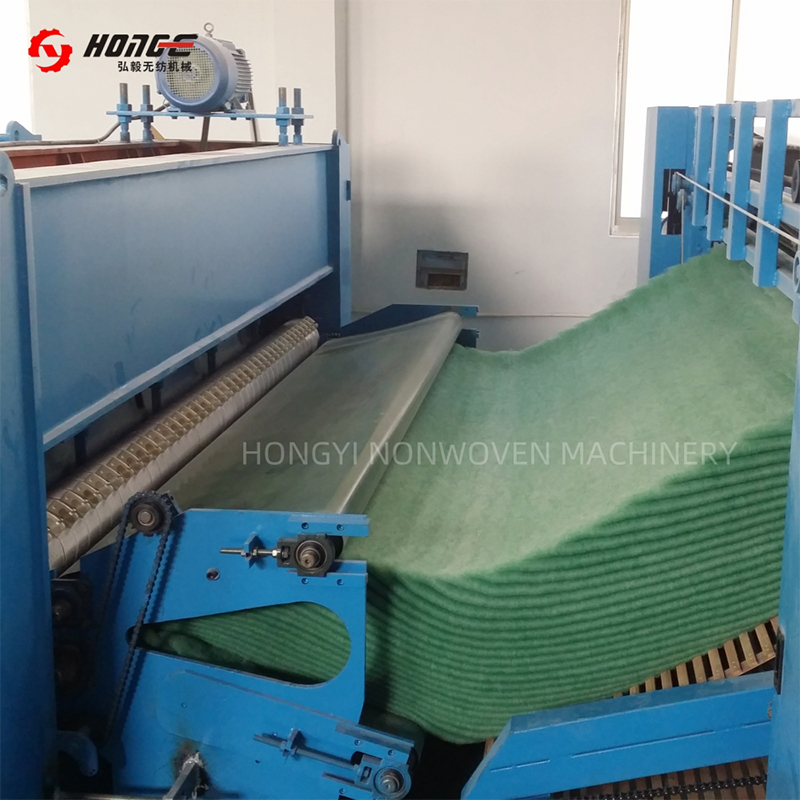

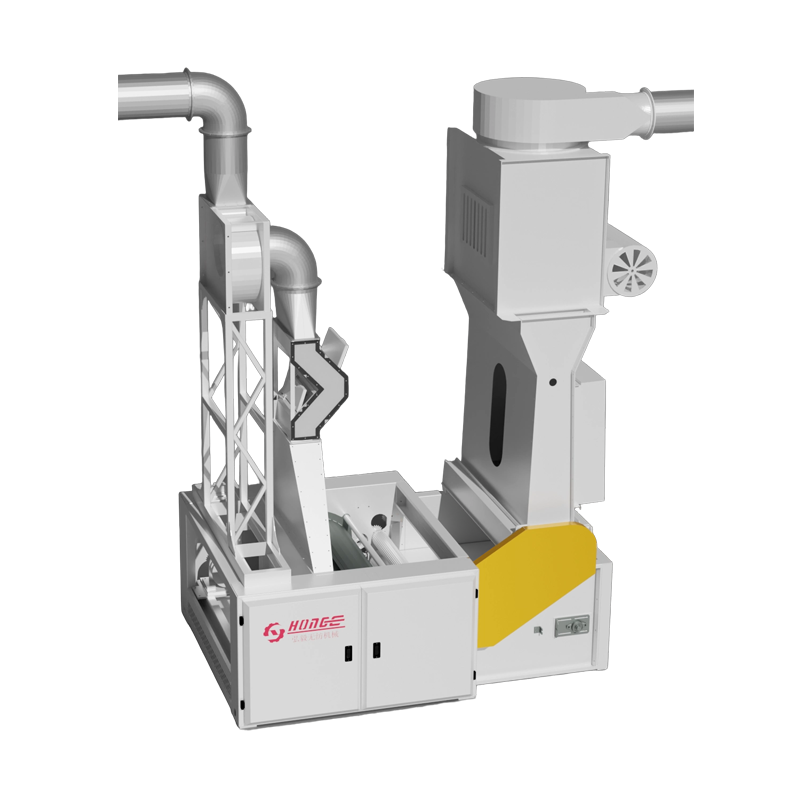

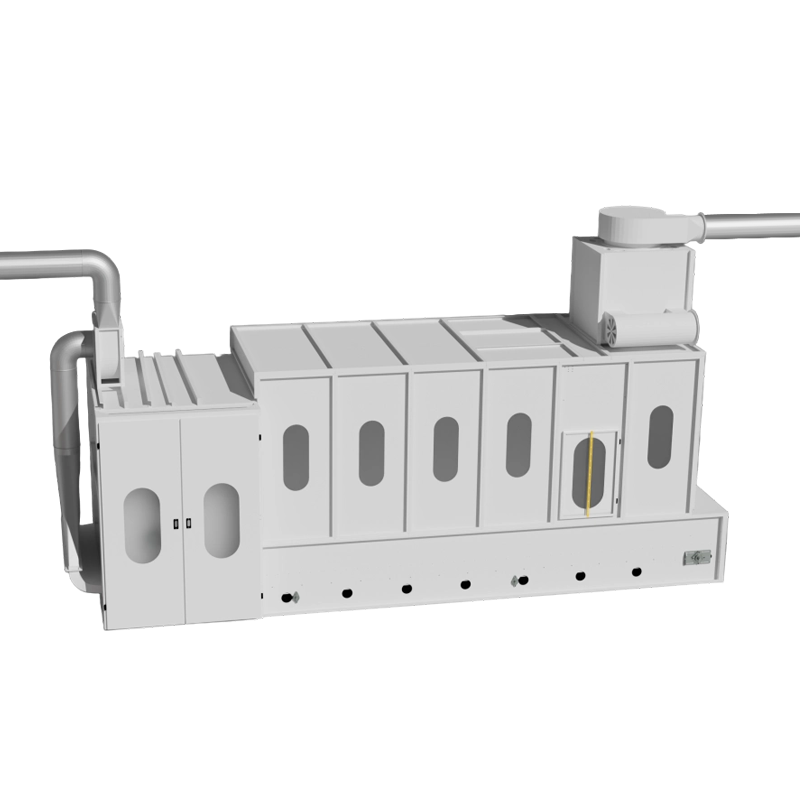

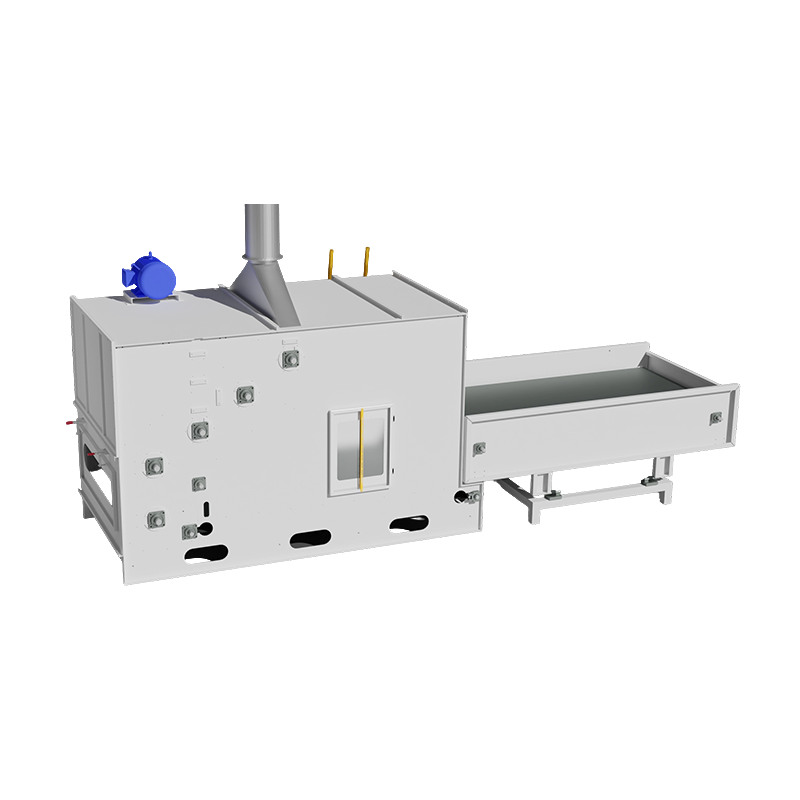

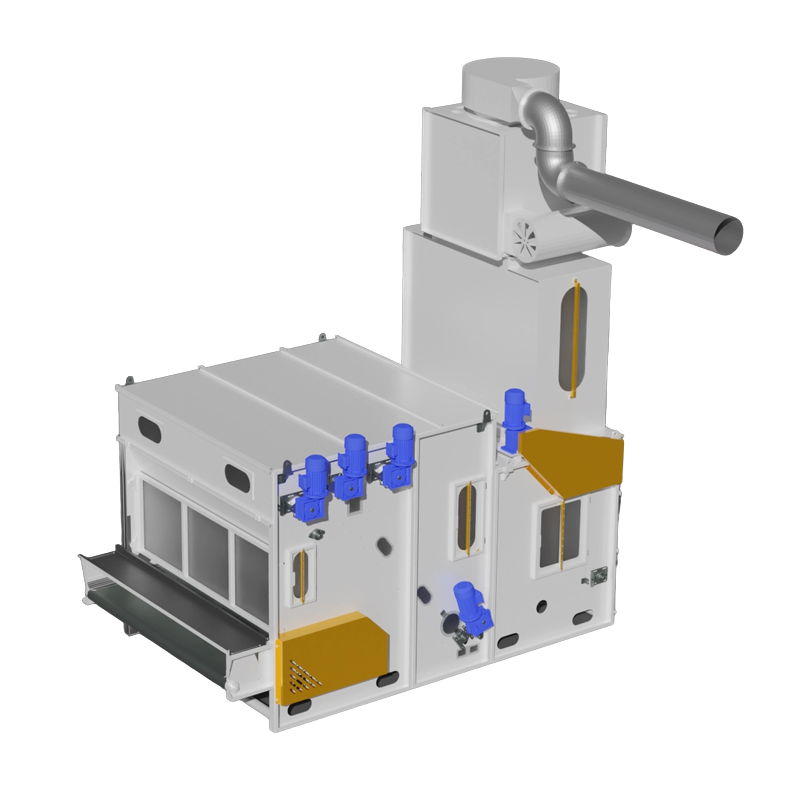

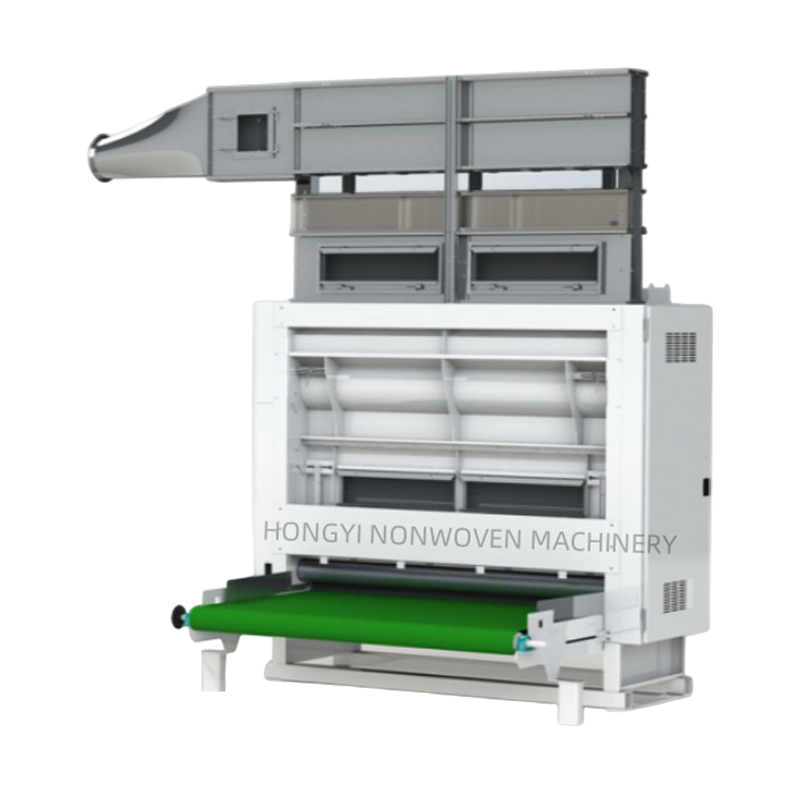

The machine is used to feed the voluminous webs from the cross lapper to the needle loom evenly with minium draft.

Function and characteristics

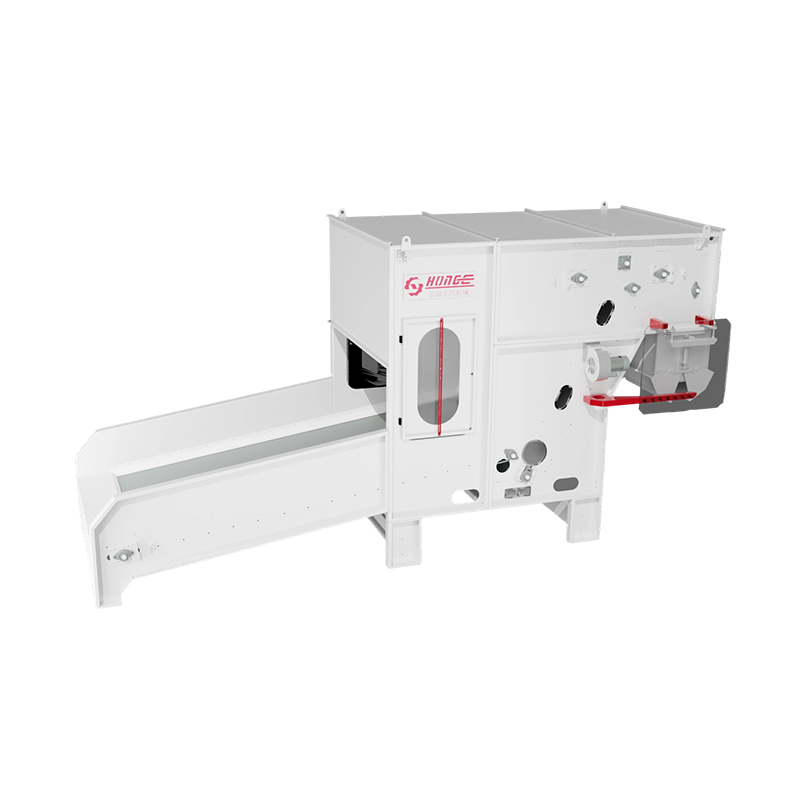

1. Nonwoven machinery pre needle loom's batt feeder is used to feed the voluminous webs from the cross lapper to the needle loom evenly with minimum draft.

2. Anti-static wedge shape feeding device and nylon-finger feeding rollers, the gap between the rollers is adjustable.

3. Inverter or servo motor driven feeding system.

4. Movable for operation and maintenance.

| Automatic Grade | Automatic |

| Customized | Customized |

| After-sales Service | One Year Warranty |

| Working Width | up to Pre-Needle Punching Machine |

| Configuration | Can Be Customized According to Customer Needs |

| Material | Mechanical Materials Are Mostly Steel and Iron |

| Specification | ≤10m |

| Origin | China |

| Production Capacity | 100 Sets/Year |